UV-resistant A02 handset specifically engineered for maritime applications

Designed specifically for demanding applications such as oil and gas platforms and sea ports, the telephone handset must deliver uncompromising performance in corrosion resistance, waterproof integrity, and resilience to extreme environmental conditions. As a specialized OEM manufacturer in this sector, we engineer every aspect of our handsets—from material selection and internal architecture to electronic components and external cable design—to operate reliably under the most challenging conditions.

To withstand corrosive and high-UV environments, we utilize UL-certified ABS, Lexan® UV-resistant PC, and anti-violent ABS materials, depending on application-specific requirements. Our handsets can be equipped with a range of speakers and microphones, allowing compatibility with various main control boards to achieve either high communication sensitivity or advanced noise cancellation.

A key differentiator of our design is the structural reinforcement aimed at maximizing environmental protection. Unlike conventional handsets, we incorporate acoustically transparent waterproof membranes over both the speaker and microphone. Combined with sealed housing construction, these enhancements enable an IP66 rating, ensuring full protection against dust and high-pressure water jets—making the handset ideal for permanent outdoor and marine installation.

Main Components:

- Casing: Made of specialized, riot-resistant ABS or UV-resistant PC SABRE material, this UV-resistant product withstands long-term weathering and fading, ensuring durability and safety in marine environments.

- Cable: Utilizes a rugged, coiled PU cable, with other materials available, such as PVC or Hytrel, for enhanced flexibility and resistance to harsh marine environments.

- Rope: Equipped with a high-strength, coiled rope, retractable to 150-200 cm, it withstands rigorous use on board.

- Transmitter and Receiver: Featuring a puncture-resistant, high-fidelity design and an optional noise-canceling microphone, it ensures clear communication even in high-noise marine environments.

- Cap: Reinforced with an adhesive cap, it provides vandalism protection and ensures durability in demanding applications.

Features:

- Marine handsets are a vital component of a ship's communication system, enabling immediate contact with the bridge or emergency control center in the event of an alarm or emergency. Siniwo handsets are designed for reliability, ease of operation, and long-term use, with a rugged construction ideal for offshore operations. Dustproof and Waterproof: With an IP66 rating, it's ideal for use in wet, dusty, or exposed environments such as decks, engine rooms, and corridors.

- Enclosure: Made of high-strength, vandal-resistant ABS material, it's corrosion-, impact-, and vandal-resistant, with a smooth surface for a pleasant feel.

- System Compatibility: Can be integrated with a ship's alarm system or multi-line telephone network, and connected to a central control unit.

We provide a comprehensive line of certified marine-grade telephone handsets engineered for maximum reliability in emergency maritime communication. Designed to perform under the most demanding conditions, they are specifically built to resist corrosion, moisture, and impact in fully exposed locations—including main decks, external walkways, and remote monitoring stations.

|

Item |

Technical data |

|

Waterproof Grade |

IP65 |

|

Ambient Noise |

≤60dB |

|

Working Frequency |

300~3400Hz |

|

SLR |

5~15dB |

|

RLR |

-7~2 dB |

|

STMR |

≥7dB |

|

Working Temperature |

Common:-20℃~+40℃ Special: -40℃~+50℃ (Please tell us your request in advance) |

|

Relative Humidity |

≤95% |

|

Atmospheric Pressure |

80~110Kpa |

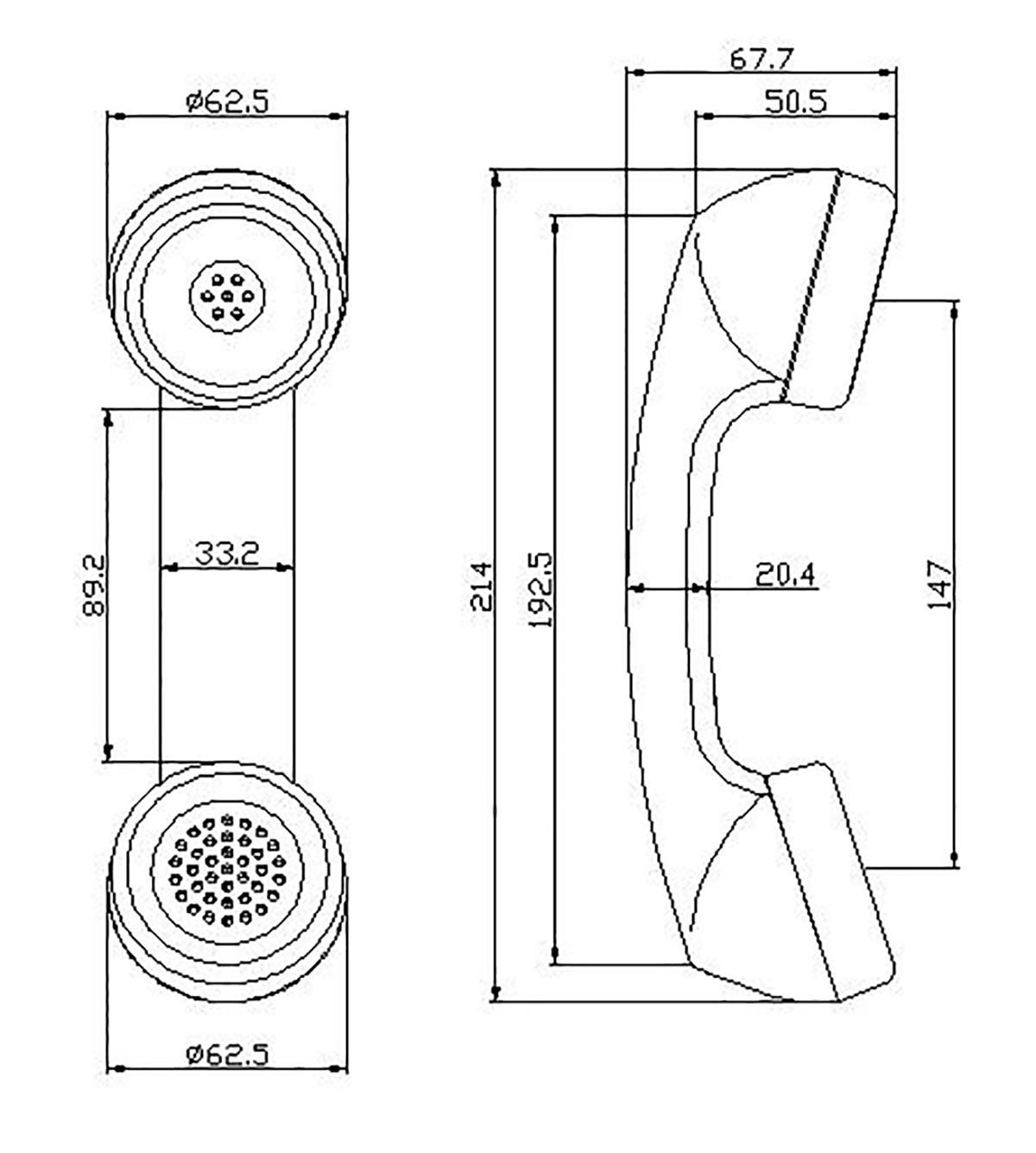

A detailed dimensional drawing of the handset is included in each instruction manual to assist you in verifying whether the size meets your requirements. Should you have any specific customization needs or require modifications to the dimensions, we are pleased to offer professional redesign services tailored to your demandings.

Our available connectors include the following types and other customized connector:

2.54mm Y Spade Connector – Ideal for secure and stable electrical connections, widely used in power equipment and industrial control systems that require high reliability.

XH Plug (2.54mm pitch) – This connector, often provided with an 180mm ribbon cable, is one of our standard options suitable for both indoor and outdoor equipment, commonly applied in electronic control systems and internal device wiring.

2.0mm PH Plug – Suitable for compact devices with limited space, such as portable communication equipment and small electronic instruments.

RJ Connector (3.5mm) – Often used in communication and network equipment, providing stable signal transmission for telephone systems and data communication devices.

Two-channel Audio Jack – Supports stereo audio output, perfect for audio communication devices, broadcasting equipment, and professional audio systems.

Aviation Connector – Designed with robust structure and high reliability, especially suitable for military handsets and related military equipment that require operation in extreme environments. It offers excellent resistance to vibration, impact, and harsh conditions.

6.35mm Audio Jack – A standard size commonly used in professional audio and broadcasting equipment, musical instruments, and high-fidelity audio systems.

USB Connector – Provides data transfer and power supply capabilities for modern digital devices, including computers, charging devices, and various communication equipment.

Single Audio Jack – Suitable for mono audio transmission, often used in intercoms, industrial headsets, and public address systems.

Bare Wire Termination – Offers flexibility for custom wiring and field installations, allowing engineers to adapt to specific connection requirements during equipment maintenance and installation.

We also provide customized connector solutions based on specific client requirements. Should you have special needs regarding pin layout, shielding, current rating, or environmental resistance, our engineering team can assist in developing a connector that matches your system perfectly.We'll be glad to recommend the most suitable connector after knowing your application environment and device.

Our standard handset colors are black and red. If you require a specific color outside of these standard options, we offer custom color matching services. Please provide the corresponding Pantone color. Please note that custom colors are subject to a minimum order quantity (MOQ) of 500 units per order.

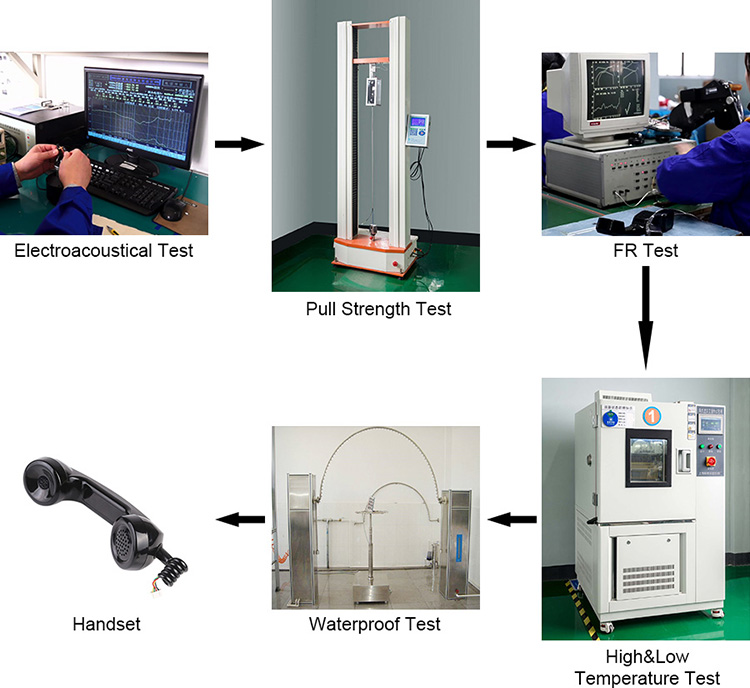

Our end-to-end quality control process begins with rigorous validation of incoming materials and continues throughout the entire assembly process. This system is supported by first-article inspection, real-time in-process checks, automated online testing, and comprehensive pre-storage sampling.

Furthermore, each batch undergoes a mandatory pre-shipment inspection by our sales-support quality team, who provide clients with detailed verification reports. All products are backed by a full one-year warranty—covering defects under normal operation—and we offer affordable maintenance services beyond the warranty period to extend product lifecycle and ensure sustained performance.

To guarantee durability and functionality across various environments, we conduct extensive testing including:

- Salt Spray Test

- Tensile Strength Test

- Electroacoustic Test

- Frequency Response Test

- High/Low Temperature Test

- Waterproof Test

- Smoke Test

We tailor our testing protocols to align with industry-specific requirements, ensuring that every handset performs reliably