Hazardous oil and gas environments demand ATEX-certified communication. Specialized industrial telephones play a critical role. They ensure operational safety and efficiency in these volatile areas. Inadequate communication solutions pose severe risks. They can lead to catastrophic failures in explosive atmospheres. An ATEX telephone provides essential protection. Businesses rely on Explosion Proof Telephones (ATEX) to prevent accidents. These devices maintain vital connections where standard equipment fails.

Key Takeaways

- ATEX certification is a must for phones in oil and gas areas. It stops explosions and keeps workers safe.

- Different hazardous areas need specific ATEX phones. These areas are classified by gas, dust, and how often danger is present.

- ATEX phones use special ways to prevent explosions. These include strong cases and limiting electrical power.

- Good ATEX phones have features like high IP ratings for water and dust. They also have long-lasting batteries and connect to other safety systems.

- Choosing an ATEX phone means looking at your needs, picking a good seller, and ensuring proper setup and care.

Understanding ATEX Certification for Oil & Gas ATEX Telephones

Defining ATEX Certification and Its Scope

ATEX certification is a European Union directive. It outlines requirements for equipment and protective systems in potentially explosive atmospheres. This directive sets standards manufacturers must follow. It ensures worker safety and prevents explosions in hazardous environments within the EU and the UK. Products undergo rigorous testing by a Notified Body, an independent third party designated by the EU. Manufacturers compile and submit technical files, including drawings, safety calculations, and risk assessments. Once certified, the product receives CE and Ex markings. A Declaration of Conformity is then issued. The ‘Ex’ symbol indicates suitability for explosive atmospheres. It must include additional information, such as the protection category and the type of explosive atmosphere it handles.

Why ATEX Compliance is Non-Negotiable

ATEX compliance is a legal requirement within the European Union. Directive 2014/34/EU mandates that equipment for explosive atmospheres must meet specific health and safety requirements. ATEX certification demonstrates compliance with these regulations. It becomes a legal necessity for manufacturers and suppliers entering the European market. This framework ensures the safety of equipment operating in potentially explosive environments. It protects personnel and assets from catastrophic incidents. Choosing an ATEX telephone ensures adherence to these critical safety standards.

Global Standards: ATEX, IECEx, and North American Equivalents

Different regions use various standards for hazardous area equipment. ATEX is mandatory within the European Union. It is a requirement for companies operating or selling within this region. IECEx is an internationally recognized framework. It facilitates global trade in hazardous area equipment. North American standards, like NFPA 70 NEC, apply in the United States. OSHA and Nationally Recognized Testing Laboratories (NRTLs) oversee these.

Here is a comparison of these key standards:

| Standard | Geographic Focus | Classification Method |

|---|---|---|

| ATEX | European Union | Zones (0/20, 1/21, 2/22) |

| IECEx | International | Zones (similar to ATEX) |

| North American (NFPA 70 NEC) | United States | Class/Division |

Both ATEX and IECEx aim to ensure safety in environments at risk for explosions. Their key differences lie in geographic recognition and detailed certification processes. IECEx provides a consistent, standardized approach to equipment safety in hazardous locations. This promotes international trade.

Classifying Hazardous Areas for ATEX Telephone Selection

Selecting the correct ATEX telephone requires a clear understanding of hazardous area classifications. These classifications define the risk level of an explosive atmosphere. They guide the choice of appropriate equipment. Different regions use various systems to categorize these dangerous locations.

Gas and Vapor Zones (0, 1, 2)

For gases, vapors, and mists, the classification of hazardous areas into Zone 0, Zone 1, and Zone 2 depends on the frequency and duration of an explosive atmosphere. This risk level determines the specific zone.

- Zone 0: An area has an explosive atmosphere continuously or for long periods. This includes the interior of storage tanks or sumps where flammable liquids are present.

- Zone 1: An explosive atmosphere is likely to occur occasionally during normal operation. This might happen due to repair, maintenance, or leakage. Areas near pumps, valves, or flanges prone to leaks often fall into this category.

- Zone 2: An explosive atmosphere is not likely to occur during normal operation. If it does, it persists for only a short period. Well-ventilated pump rooms or open plant areas next to Zone 1 equipment are examples.

Dust Zones (20, 21, 22)

Combustible dusts also create hazardous environments. These areas classify into Zone 20, Zone 21, and Zone 22.

- Zone 20: Ignitable concentrations of combustible dust or fibers are present continuously or for extended periods under normal operating conditions.

- Zone 21: Ignitable concentrations of combustible dust or fibers are likely to occur occasionally during normal operations. This can happen during repair, maintenance, or due to leakage.

- Zone 22: Ignitable concentrations of combustible dust or fibers are not likely to occur under normal operating conditions. If they do, they persist only for a short period.

North American Divisions (Class I, II, III; Division 1, 2)

North America uses a different system for hazardous locations. This system categorizes areas by Class and Division.

- Class I: These locations contain flammable gases or vapors. Examples include hydrogen, acetylene, gasoline vapors, and methane.

- Class II: These locations contain combustible or electrically conductive dust. This includes metal dusts, wood dust, carbon-based dust, and organic dust.

- Class III: These areas have sufficient ignitable fibers to pose a fire hazard. Cotton lint, flax, and rayon are examples.

Beyond the Class, locations also have a Division:

- Division 1: This denotes a high probability of ignition. The hazardous substance is continuously, periodically, or intermittently present.

- Division 2: This indicates a low probability of ignition under normal operating conditions. Ignitable mixtures may form only due to leaks, spills, or equipment malfunctions.

Decoding ATEX Telephone Protection Parameters

Selecting the right ATEX equipment involves understanding specific protection parameters. These parameters ensure the equipment operates safely in hazardous environments. They detail how a device prevents ignition.

Gas and Dust Group Classifications

ATEX standards classify hazardous substances into specific groups. These groups determine the type of equipment suitable for an area. They categorize gases and dusts based on their ignition properties.

ATEX standards classify gas groups IIA, IIB, and IIC. They base this on the ease of ignition by an electric spark. Group IIC includes substances like hydrogen. It is the most easily ignited. This group demands the highest safety requirements. Dust groups IIIA, IIIB, and IIIC categorize dusts by their properties. Groups IIIA and IIIB cover non-conductive dusts, such as flour dust. These can be coarse or fine. Group IIIC consists of electrically conductive dusts, like metal dust. This poses a significant hazard due to its potential to cause short circuits. Tools approved for Group IIIC have the most stringent requirements. Such tools are also suitable for areas with IIIA and IIIB dusts.

- Gas Groups (Group II):

- IIC: Acetylene and hydrogen group.

- IIB: Ethylene group.

- IIA: Propane group (oil & gas).

- Dust Groups (Group III):

- IIIC: Conductive dust.

- IIIB: Non-conductive dust.

- IIIA: Combustible flyings.

Group II covers explosive gas atmospheres. IIA includes atmospheres containing propane or equivalent hazard gases/vapors. IIB covers atmospheres with ethylene or equivalent hazard gases/vapors. IIC includes atmospheres containing acetylene or hydrogen or equivalent hazard gases/vapors. Group III covers explosive dust atmospheres. IIIA includes atmospheres with combustible flyings. IIIB covers atmospheres with non-conductive dust. IIIC includes atmospheres with conductive dust.

Matching the equipment’s certification to the specific gas group present in the hazardous area is crucial. Different gases and vapors categorize into specific gas groups based on their properties. Equipment suitable for one gas group may not be appropriate for another. For instance, Group I equipment designs for mining environments. Group II is for industrial areas.

| ATEX Group | Definition | Examples | Safety Measures for Telephones |

|---|---|---|---|

| Gas Group IIA | Least explosive gases | Propane, butane | Standard flameproof enclosures |

| Gas Group IIB | Moderately explosive gases | Ethylene, MEK | Enhanced sealing, stronger enclosures |

| Gas Group IIC | Most explosive gases | Hydrogen, acetylene | Advanced flameproof designs, equipment withstanding high pressures |

| Dust Group IIIB | Non-conductive dusts | Flour, sugar, wood dust | Dust-tight equipment enclosures, preventive measures against dust accumulation |

| Dust Group IIIC | Conductive dusts | Aluminum dust, coal dust | Measures against static charges, specialized enclosures |

ATEX classifications for gas and dust groups are essential. They help understand the hazard level posed by various substances in explosive atmospheres. These group ratings categorize substances based on their flammability, conductivity, and other properties. They directly influence the required safety features of ATEX-certified telephones.

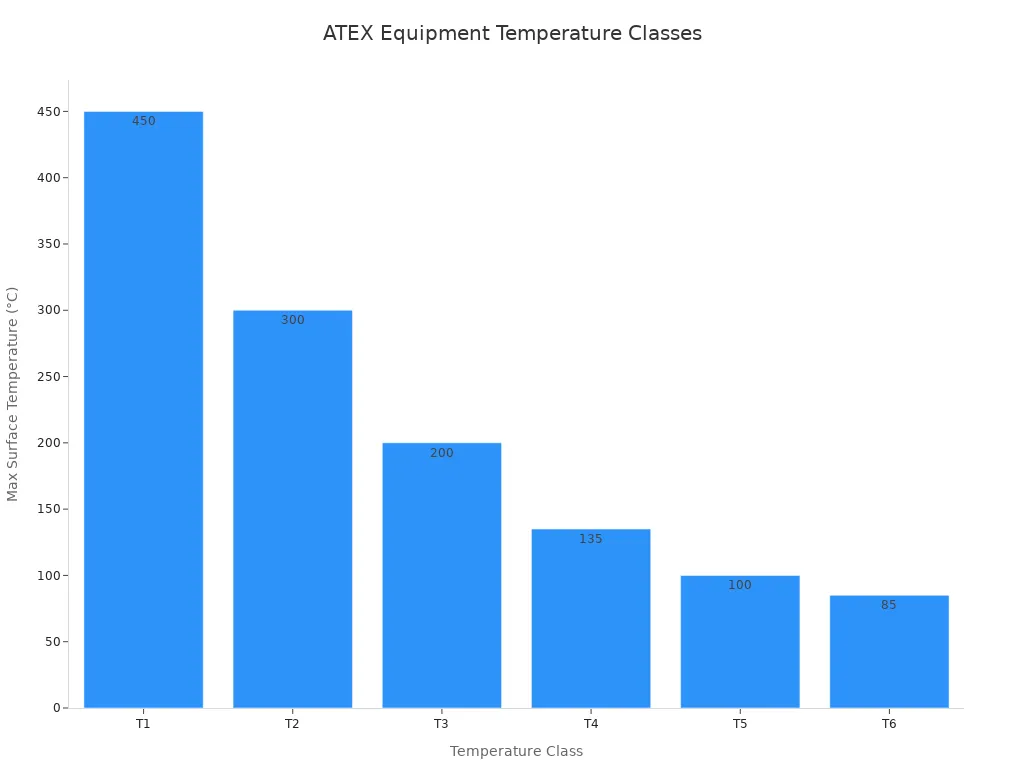

Temperature Classes (T-Ratings) for ATEX Telephones

Temperature classes, or T-ratings, specify the maximum surface temperature an ATEX-certified device can reach. This temperature must remain below the ignition temperature of the surrounding hazardous atmosphere.

- T1: 450°C maximum surface temperature

- T2: 300°C maximum surface temperature

- T3: 200°C maximum surface temperature

- T4: 135°C maximum surface temperature

- T5: 100°C maximum surface temperature

- T6: 85°C maximum surface temperature

| Temperature Class | Maximum Surface Temperature |

|---|---|

| T1 | 450°C |

| T2 | 300°C |

| T3 | 200°C |

| T4 | 135°C |

| T5 | 100°C |

| T6 | 85°C |

The ambient temperature of an environment directly influences the required T-rating for an ATEX telephone. For instance, a device initially rated T4 at an ambient temperature (Ta) of 40 °C might see its T-class downgraded to T3. This happens if the ambient temperature rises to 60 °C. This indicates that higher ambient temperatures necessitate a lower (less stringent) T-class rating for the same device. Its maximum safe surface temperature reduces to prevent ignition.

Equipment Protection Levels (EPLs)

Equipment Protection Levels (EPLs) define the level of safety equipment provides in hazardous areas. They indicate the risk of equipment becoming an ignition source.

| EPL | Definition | Zone Compatibility | Key Features |

|---|---|---|---|

| Ga | Highest protection, safe even with two simultaneous faults. | Zone 0 (continuously present explosive atmospheres). | Prevents ignition under all circumstances; operates safely with continuous exposure to explosive gases. |

| Gb | High protection, safe during normal operation and single fault. | Zone 1 (explosive atmospheres likely during normal operations). | Enhanced safety for intermittent risks; flameproof enclosures and intrinsic safety. |

| Gc | Basic protection, safe during normal operation; may have additional measures for fault situations. | Zone 2 (explosive atmospheres unlikely or for short durations). | Designs for minimal risk; may shut down on fault to prevent ignition. |

| Ex Da | Highest protection, safe even with two simultaneous faults. | Zone 20 (continuously present explosive dust clouds). | Intrinsically safe design; sealed enclosures to prevent dust ingress. |

| Ex Db | High protection, safe during normal operation and single fault. | Zone 21 (explosive dust clouds occur intermittently). | Dust-tight enclosures; proper grounding to eliminate static discharge. |

| Ex Dc | Basic protection in normal conditions; may lack additional fail-safes. | Zone 22 (explosive dust clouds appear briefly and rarely). | Minimized surface temperature; static discharge prevention. |

Common Protection Methods (Ex d, Ex ia, Ex e)

Manufacturers employ various protection methods to ensure ATEX-certified equipment operates safely in hazardous areas. These methods prevent ignition of explosive atmospheres. Understanding them helps in selecting the right equipment for specific risks.

Flameproof Enclosure (Ex d)

Flameproof enclosures, known as ‘Ex d’, are robust protection methods. They contain an explosion if it occurs inside the equipment. This prevents the flame from spreading to the surrounding explosive atmosphere. An ATEX telephone using Ex d protection allows an internal explosion. However, the enclosure must not let the explosion escape outside. This design assumes explosive atmospheres can enter the enclosure. It also assumes non-Ex equipment inside might create ignition sources like heat or sparks. Therefore, the enclosure must withstand the pressure of an internal explosion.

A key safety mechanism in Ex d enclosures is the flame path. Mechanical connections, such as those between the enclosure and its cover, form this path. The flame path controls the release of pressure. It extinguishes flames and cools escaping gases. This prevents a secondary ignition outside the enclosure. Damage to the flame path, like pitting or scratches, makes the protection ineffective. This risks a secondary explosion outside the enclosure.

Newer concepts in Ex d protection include decompression panels and flame arresters. These allow for thinner-walled enclosures, reducing weight and cost. A decompression panel ruptures at about 0.1 bar g. This directs explosion effects to the environment. Behind the panel, a filter made of steel mesh layers performs several safety functions. It extinguishes flames and cools exhaust gases. It also disperses explosion pressure. This ensures residual pressure and cooled exhaust gases escape below the auto-ignition temperature.

Ex d designs also focus on heat dissipation. They prevent generated heat from reaching ignition temperatures for gases or dust. This involves heat sinks, special heat-conducting materials, or designs that enhance natural air circulation. Material selection is crucial. Manufacturers choose materials for their ability to withstand internal explosion pressures. They also consider corrosion resistance and durability in harsh environments. Common materials include aluminum, stainless steel, and high-strength alloys. Equipment must meet rigorous certification standards. It must also comply with international and local safety regulations. Certifying bodies conduct extensive testing. They verify explosion-proof capabilities, including flame path adequacy and enclosure robustness. Flameproof enclosures are suitable for high-risk areas with gases, vapors, or mists under Group IIA, IIB, and IIC.

Intrinsic Safety (Ex ia)

Intrinsic safety, or ‘Ex ia’, is another common protection method. It limits the electrical and thermal energy within a circuit. This prevents sparks or hot surfaces from igniting an explosive atmosphere. Ex ia equipment operates at very low power levels. It cannot produce enough energy to cause an ignition, even under fault conditions. This makes it suitable for Zone 0 and Zone 20 areas, where explosive atmospheres are continuously present.

Increased Safety (Ex e)

Increased safety, or ‘Ex e’, prevents ignition by ensuring no sparks or hot surfaces occur during normal operation. This method focuses on robust construction and high-quality components. It uses increased creepage distances and clearances. It also employs enhanced insulation and secure connections. Ex e equipment prevents ignition by avoiding any potential ignition source. It does not contain an explosion like Ex d. It also does not limit energy like Ex ia. Instead, it prevents the conditions for ignition from ever arising. This method is typically used in Zone 1 and Zone 2 areas.

Essential Features for Oil & Gas ATEX Telephones

Oil and gas environments demand communication devices with specific features. These features ensure safety, durability, and effective communication. Specialized ATEX telephones meet these rigorous requirements.

Ingress Protection (IP Ratings) for Durability

Ingress Protection (IP) ratings are crucial for ATEX telephones. The international standard IEC 60529 defines these ratings. An IP rating classifies how effectively an enclosure protects electrical equipment. It guards against solid particles like dust, sand, or tools. It also protects against liquids such as rain, splashes, jets, or immersion.

An IP rating consists of the letters ‘IP’ followed by a two-digit code, for example, IP67. The first digit indicates protection against solids. The second digit refers to protection against moisture. An ‘X’ means no test was performed for that category.

The first digit denotes the enclosure’s resistance to solid objects. This includes everything from the finest dust particles to larger entities. The scale runs from 1 to 6. Level 1 represents rudimentary protection. Level 6 signifies an entirely dust-tight enclosure. This digit provides valuable information about how effectively the enclosure guards against solid matter intrusion.

| Digit | Protection Level (Solids) | Example (Solids) |

|---|---|---|

| 0 | No protection | – |

| 1 | Objects ≥ 50 mm | Hand contact |

| 2 | Objects ≥ 12.5 mm | Finger |

| 3 | Objects ≥ 2.5 mm | Tools, thick wires |

| 4 | Objects ≥ 1 mm | Screws, small tools |

| 5 | Dust-protected | Limited dust ingress |

| 6 | Dust-tight | Complete dust seal |

The second digit characterizes the enclosure’s resistance to water ingress. This digit exclusively pertains to protection against water. It does not encompass other liquids like oil or coolant. The rating ranges from 0 to 8. Level 0 indicates no water protection. Level 8 shows a waterproof enclosure capable of enduring prolonged submersion. This digit informs users about the level of water resistance an enclosure offers.

| Digit | Protection Level (Liquids) | Effective Against (Liquids) |

|---|---|---|

| 0 | No protection against liquids/moisture | |

| 1 | Dripping water | Dripping water (vertically falling drops) shall have no harmful effect on the object when mounted in an upright position onto a turntable and rotated at 1 RPM. |

| 2 | Dripping water when tilted at 15° | Vertically dripping water shall have no harmful effect when the object is tilted at an angle of 15° from its normal position. |

| 3 | Spraying water | Water falling as a spray at any angle up to 60° from the vertical shall have no harmful effect, utilizing either: a) an oscillating fixture or b) A spray nozzle with a counterbalanced shield. |

| 4 | Splashing of water | Water splashing against the object from any direction shall have no harmful effect, utilizing either: a) an oscillating fixture or b) A spray nozzle with no shield. |

| 5 | Water jets | Low-pressure jets |

| 6 | Powerful jets | High-pressure water |

| 7 | Temporary immersion | Up to 1 m, 30 min |

| 8 | Continuous immersion | Depth & time specified by manufacturer |

| 9K | High-pressure, high-temperature jets | Industrial cleaning |

For oil and gas environments, especially offshore drilling platforms, an IP68 rating or higher is recommended. This ensures reliability in wet or dusty worksites. Many industrial ATEX telephones also feature IP67 environmental ratings with NPT conduit entries or IP66 protection types as per EN60529. These ratings guarantee the device withstands harsh conditions.

Robustness and Environmental Resistance

Oil and gas facilities present extremely challenging conditions. Telephones in these areas require exceptional robustness and environmental resistance. Manufacturers use specific materials and construction techniques to achieve this.

- Materials for Body and Casing: Corrosion-resistant aluminum alloy, stainless steel, SMC (Sheet Molding Compound), and heavy metal provide robust construction.

- Enclosures: Robust enclosures, often made from cast aluminum or stainless steel, contain internal explosions. They prevent these explosions from igniting external gases.

- Sealing: Specialized sealing, including flame paths or labyrinth seals, cools and dissipates heat from escaping gases during an internal explosion. It also prevents ingress of dust, water, and corrosive substances.

- Intrinsic Safety: Components are designed to limit electrical energy below ignition levels for flammable gases or vapors. This prevents sparks or excessive heat.

- Sealed Components: Microphones, speakers, and wiring are sealed. This prevents ingress of dust, moisture, and corrosive substances.

- Non-Sparking Components: Every internal part is specifically chosen or designed not to spark. This includes low-power circuits, encapsulated sensitive components, buttons, and wires.

- Rugged Handsets: Handsets are specifically designed to withstand harsh conditions and physical abuse.

- Environmental Ratings: IP66/IP68/IP69K ratings ensure dust and water resistance. NEMA 4X/6 ratings provide protection against water ingress, corrosion, and temporary submersion.

- Impact Protection: IK10 impact protection ensures durability against physical impacts.

These design choices ensure the telephone functions reliably. They also protect personnel in demanding and potentially dangerous settings.

Communication Features and System Integration

Modern ATEX telephones offer advanced communication features. They also integrate seamlessly into existing facility systems. This enhances operational efficiency and emergency response.

ATEX certified telephones support various communication protocols. Many models support Voice over IP (VoIP) communication protocols. This includes Session Initiation Protocol (SIP). This compatibility allows integration into modern IP-based communication networks. Analog communication is also available for older systems.

Integrating ATEX telephones with Public Address and General Alarm (PAGA) systems offers significant benefits:

- Enhancing Emergency Communication Capabilities: Integration strengthens emergency communication. The PAGA system automatically broadcasts messages when an alarm sounds. Personnel use ATEX telephones to report details or ask for help. This ensures quick sharing of critical information.

- Improving Safety and Response Protocols: Unified systems lead to better safety. They instantly alert specific teams for a coordinated response. For example, they evacuate personnel during a gas leak. Maintenance teams receive direct alerts.

- Achieving Regulatory Compliance: Integrating communication systems helps facilities meet strict safety regulations. It demonstrates robust emergency procedures to authorities. This also helps avoid fines.

- Boosting Operational Efficiency: Integrated systems streamline daily operations. Workers quickly report issues from any location using ATEX telephones. This reduces downtime. It also makes routine announcements easier through the PAGA system.

- Realizing Cost-Effectiveness Through Integration: Initial setup has costs. However, integration saves money over time. It avoids purchasing separate, incompatible systems. It reduces maintenance costs. It also potentially requires less staff training.

These integrated communication solutions are vital for safe and efficient operations in oil and gas environments.

Power Options and Battery Life Considerations

Reliable power is essential for communication devices in oil and gas environments. These locations often lack easy access to charging points. Therefore, ATEX-certified telephones need robust power solutions. They must offer extended battery life. This ensures continuous operation during critical tasks and emergencies.

Battery capacity is a primary concern for portable devices. For extended field use, a battery capacity of 4000mAh is a minimum. Many rugged outdoor phones now feature capacities of 10,000mAh or more. These larger batteries provide longer operational times.

Users can expect varying battery performance based on usage patterns. The following table outlines typical expectations:

| Characteristic | Range/Expectation |

|---|---|

| Battery Capacity | 4000–10000 mAh |

| Standby Time | Up to 72+ hours |

| Moderate Use | 48–72 hours |

| Heavy Use | A full day |

| Continuous Use | Several days (for some models exceeding 5000 mAh) |

Several factors contribute to extended battery life in these specialized devices. Manufacturers design these phones for maximum efficiency.

- High-capacity batteries, ranging from 5,000mAh to 10,000mAh, are significantly larger than those in average smartphones.

- Energy-efficient processors, often modern, low-power chipsets, maximize battery efficiency.

- Optimized software includes power-saving modes and adaptive brightness. These features reduce power consumption.

- Power-saving modes, efficient processors, and low-power displays all contribute to extended runtime.

- Some units support hot-swappable batteries. This allows for uninterrupted operation. Workers can replace a depleted battery without powering down the device. This feature is crucial for continuous shifts and remote locations.

Choosing the right power option ensures that communication remains available when it matters most. This directly impacts safety and operational continuity in hazardous areas.

Strategic Selection of Your ATEX Telephone

Choosing the right communication device for hazardous environments requires careful thought. Businesses must consider many factors. This ensures safety, efficiency, and compliance.

Assessing Operational Needs and Environment

Selecting an ATEX telephone begins with a thorough assessment. Businesses must understand their specific operational needs and the environment. They identify the exact hazardous zones where the telephone will operate. This includes gas and dust classifications, temperature classes, and equipment protection levels. They also consider the physical conditions. These include extreme temperatures, humidity, corrosive substances, and potential for physical impact.

Next, businesses evaluate communication requirements. They determine if they need voice communication, data transfer, or both. They also consider integration with existing systems like Public Address and General Alarm (PAGA). The number of users and the required coverage area also play a role. Understanding these details helps match the telephone’s features to the job.

Vendor Selection and Product Reliability

Choosing a reliable vendor is crucial for ATEX communication solutions. Businesses should look for manufacturers with a strong track record. They evaluate vendors based on several key criteria.

First, compliance certifications are essential. A reputable vendor holds certifications like ATEX Directive 2014/34/EU. They also possess ISO 9001 for quality management and ISO 80079 for explosive atmospheres. Other important marks include CE, NRTL, and the distinctive Community Mark (‘Ex’ in a hexagon). For equipment in Zones 0 and 1, a Notified Body evaluates the product. This includes an EU Type Certificate and a Quality Audit (QAN). These certifications demonstrate adherence to strict safety and quality standards.

Second, businesses consider the total cost of ownership (TCO). This includes more than just the initial purchase price. They evaluate maintenance costs, durability, and upgradeability. Products meeting higher safety certifications often last longer in harsh environments. Long-term return on investment (ROI) comes from reduced downtime and lower maintenance expenses. Regulatory compliance is an ongoing process. Standards evolve, requiring continuous updates and re-certifications. This highlights the need for long-term vendor support.

Third, vendors must offer robust customer support and after-sales service. This includes readily available technical assistance for installation and troubleshooting. Clear warranty policies and efficient repair services are also important. Access to spare parts ensures long-term maintenance. Reliable suppliers minimize downtime. They often offer training programs for client staff. Businesses should review testimonials and case studies. These resources offer valuable insights into a supplier’s performance and product effectiveness. They also show customer satisfaction.

Installation, Maintenance, and Support

Proper installation and ongoing maintenance are vital for ATEX telephones. They ensure long-term operational safety and compliance.

Installation requires qualified personnel. Individuals installing the equipment must have ATEX compliance training. They follow the detailed installation instructions provided by the manufacturer. Proper grounding and bonding procedures prevent static electricity buildup. All equipment, including telephones, must be ATEX-certified. This minimizes ignition risks. Installers understand zoning requirements. They classify hazardous areas to select equipment with the appropriate protection level. They also implement intrinsically safe design principles. This limits electrical and thermal energy in circuits. This prevents ignition, especially in high-risk environments. Installers follow guidelines for proper placement, clearance, and orientation. They ensure correct wiring using specified cable types and sizes. This prevents sparking or overheating. They also account for environmental factors like temperature, humidity, or corrosive substances. After installation, thorough system testing confirms all components function as expected.

Regular maintenance ensures continued safety. Businesses establish and strictly adhere to regular inspection schedules. Qualified personnel perform these inspections. They include visual checks, functional tests, and non-destructive testing. Regular cleaning and preventive maintenance use approved agents and procedures. This eliminates contaminants and prevents wear and tear. Businesses maintain detailed records of all maintenance, inspections, and repairs. This helps with compliance, scheduling, and performance insights. Firmware and software should always run the latest versions. This enhances security and functionality. Worn-out parts must be replaced immediately with original manufacturer’s parts. This maintains device integrity and safety. All operators and personnel receive proper training. This covers operational parameters, safety protocols, and emergency response.

Maintenance tasks include:

- Visual Inspection: Check for physical damage, corrosion, loose connections, and proper sealing. Ensure all labels and markings are legible.

- Functional Testing: Verify all device functions operate correctly. This includes checking buttons, displays, sensors, and communication modules.

- Battery Health Check: Monitor battery life, charge cycles, and overall performance. Replace batteries as recommended.

- Software/Firmware Updates: Regularly update device software and firmware for optimal performance, security, and compliance.

- Cleaning: Clean devices using approved methods to prevent buildup that could compromise safety.

- Calibration: Calibrate sensors and measurement instruments periodically to maintain accuracy.

- Documentation Review: Keep detailed records of all maintenance activities.

- Environmental Checks: Ensure devices operate within specified environmental conditions.

- Accessory Inspection: Inspect chargers, cables, and cases for damage.

- Personnel Training: Ensure all personnel are properly trained on device use and safety.

These practices align with standards like IEC 60079-17 for inspection and maintenance. They also follow IEC 60079-14 for selection and installation. IEC 60079-19 outlines repair procedures. NFPA 70 (NEC) provides U.S. guidelines for hazardous locations.

Selecting an ATEX telephone requires careful consideration of hazardous zones, protection parameters, and essential features. Investing in compliant and reliable communication systems offers significant long-term benefits. These include enhanced safety, operational efficiency, and regulatory adherence. For tailored solutions and expert guidance, consult with specialists like Joiwo. They provide comprehensive industrial communication systems designed for demanding environments.

FAQ

What does ATEX certification mean?

ATEX certification shows equipment meets EU safety standards for explosive atmospheres. It ensures devices like telephones will not cause ignition in hazardous areas. This protects workers and prevents accidents.

Why are ATEX telephones crucial for oil and gas?

Oil and gas sites have flammable gases and dust. ATEX telephones prevent sparks or heat that could cause explosions. They ensure safe communication, which is vital for daily operations and emergencies.

What is an IP rating on an ATEX telephone?

An IP rating indicates a telephone’s protection against solids and liquids. For example, IP67 means it is dust-tight and can withstand temporary immersion in water. This ensures durability in harsh environments.

How do ATEX telephones prevent explosions?

ATEX telephones use methods like flameproof enclosures (Ex d) or intrinsic safety (Ex ia). Ex d contains explosions inside the device. Ex ia limits energy to prevent sparks. These methods stop ignition.

Can ATEX telephones connect to other communication systems?

Yes, many ATEX telephones support VoIP protocols like SIP. They can integrate with Public Address and General Alarm (PAGA) systems. This enhances emergency response and overall communication efficiency on site.

See Also

Essential Industrial Air Fryers: Top 5 Picks for High-Volume Kitchens

Mastering Your Sur La Table Air Fryer: A Comprehensive Usage Guide

Dishwasher Safety: Are Air Fryer Baskets Truly Safe to Clean?

Best Air Fryer Alternatives: Top 10 Picks Beyond BrandsMart in 2024

Air Fryer Guide: Easy Steps for Perfect Trader Joe’s Coconut Shrimp

Post time: Jan-14-2026