When you pick industrial keypads for tough places, look at standards like IP67 Mean for Industrial Keypads, ATEX certification, and zinc alloy waterproof keypad construction. These durability standards keep you safe from dangers in places with very hot or cold temperatures, water, dust, and chemicals. Industrial keypads used in clean rooms, building sites, and military jobs must stand up to shocks and dirt. Strong durability in hard environments helps keep you safe and makes your work more reliable.

Key Takeaways

- Pick industrial keypads with high IP ratings like IP67. This helps keep out dust and water in hard places. – Choose keypads made from strong materials like stainless steel and silicone rubber. These last a long time. – Look for certifications like ATEX and MIL-STD-810H. These show the keypads are safe and work well in dangerous places. – Make sure keypads pass tests like salt spray, shock, and vibration. This means they can handle tough industrial areas. – Get keypads that work in hot and cold temperatures. This helps them work in many different places.

IP Ratings Explained: What Does IP67 Mean for Industrial Keypads?

If you need a rugged industrial keyboard for hard jobs, you should know what IP67 means. This rating tells you how well the keyboard keeps out dust and water. You want your equipment to work every time, even if it gets dirty or wet. That is why durability is so important in tough places.

Tip: Always look at the IP rating before you buy a rugged industrial keyboard for your work area.

An IP67 rating gives you strong protection. Here is what it means:

- The first number, “6,” shows your rugged keyboard is dust-tight. No dust can get inside, so the parts stay clean.

- The second number, “7,” means your keyboard can go under water up to 1 meter deep for 30 minutes. This makes it a real waterproof keyboard.

- These tests make sure your rugged industrial keyboard works in dusty or wet places.

- IP67-rated rugged keyboards give you top safety and reliability in extreme conditions.

Industrial Keypads: Key Features

Rugged industrial keyboards need to do more than just block dust and water. These keyboards use silicone rubber for the keypad. This material feels soft, lasts a long time, and blocks electromagnetic interference. The keys are bigger and easy to press, even with gloves on. Rugged keyboards use copper flex circuits. These can handle heat, chemicals, and bending. Protective coatings help block UV light and bad weather. These features help your rugged industrial keyboard last longer and keep working, even when things get rough.

- Rugged keyboards are made for outdoor use and can handle dirt, liquids, and shocks.

- Many rugged industrial keyboards have LED backlighting, so you can see the keys in the dark.

- Vandal protection keeps your keyboard safe from people trying to break it.

- Rugged keyboards can take millions of presses and still work.

Rugged Industrial Keyboard Materials

The materials in your rugged industrial keyboard are very important. Here is a table that shows the most common choices and their benefits:

| Material | Advantages in Extreme Environments |

|---|---|

| Industrial Metal (Stainless Steel) | Very strong, hard to break, works in hot or cold, wet, and dusty places. Feels good to use and is great for outside. |

| Silicone Rubber | Tough, reliable, and feels good when you press the keys. Stays strong under stress and is easy to use. |

| Plastic (for comparison) | Costs less but is not as tough or strong as metal or silicone rubber. |

When you pick a rugged industrial keyboard, choose stainless steel or silicone rubber. These materials give you the best quality and last longest in tough places.

What are the requirements for salt spray testing of keypads?

Salt spray testing checks if rugged keyboards can handle tough places. It shows if they last in salty, wet air like in atex zone 2. Salt spray chambers make a mist with salty water. This is like what happens in marine or chemical plants. The test helps you see if your keyboard can fight rust and corrosion.

IP67 and IP65 Explained

Always check the IP rating when picking rugged keyboards for atex zone 2. IP ratings tell you how well your keyboard blocks dust and water. Here is a simple chart:

| Feature | IP65 Rating | IP67 Rating |

|---|---|---|

| Dust Protection | Keeps out all dust | Keeps out all dust |

| Water Protection | Stops low-pressure water jets | Stops water up to 1 meter deep |

| Suitable Environment | Good for splashes and dust | Good for wet, underwater, or humid places |

| Application to Keypads | Works for sprays and splashes | Best for lots of water or heavy moisture |

For atex zone 2, you need at least IP65 for rugged keyboards. IP67 gives even more safety. Both ratings mean your rugged industrial keyboard will work in hard places.

NEMA 4, 4X, and 12 Standards

NEMA ratings help you pick the right rugged keyboards for atex zone 2. These standards check more than just dust and water. They also look at corrosion, oil, and chemical safety. Here is what you should know:

| Standard | Protection Features | Typical Applications |

|---|---|---|

| NEMA 4 | Stops dust, water, and ice | Used outdoors and in factories |

| NEMA 4X | NEMA 4 plus stops corrosion | Used in marine and chemical places |

| NEMA 12 | Stops dust and dripping liquids | Used in indoor factories |

For atex zone 2, pick NEMA 4 or 4X for rugged keyboards. These standards make sure your rugged industrial keyboard can handle water, dust, and chemicals.

Note: Always check what atex and atex zone 2 need before you use rugged keyboards. Following these rules keeps your keyboard safe and working well.

Salt Spray Testing: Specific Requirements

When you test rugged keyboards for atex zone 2, you must follow strict rules:

- Use sodium chloride solution with 50 ± 5 g/l.

- The water must be very pure, grade 3 or better.

- The pH should be between 6.5 and 7.2.

- The test chamber must not rust and must keep the same temperature.

- Spray fine salt fog for up to 25 days, with at least 15 minutes each hour.

- Holders for the keyboard samples must be glass or plastic, not metal.

Salt spray testing shows if your rugged industrial keyboard will last in atex zone 2. This test copies the salty, wet air in real factories. You can trust rugged keyboards that pass these tests to work in the hardest places, even those needing atex and waterproof features.

Shock & Vibration Resistance: Key Considerations for Heavy Machinery

Industrial sites like atex zone 2 demand more from your rugged keyboards than just water and dust protection. You need devices that can handle constant movement, sudden impacts, and harsh shocks. When you use a rugged keyboard in atex zone 2, you want to know it will not fail during a critical moment. This is why shock resistance and vibration testing matter so much for atex and rugged keyboards.

Shock Resistance

Heavy machinery in atex zone 2 creates strong shocks. If your rugged keyboards cannot handle these, you risk losing control or stopping work. Shock resistance means your keyboard can take hits, drops, or bumps and still work. In atex zone 2, rugged keyboards often face sudden impacts from tools or falling objects. These keyboards are built to survive drops from several feet, which is common in atex and industrial settings. When you choose a rugged keyboard for atex zone 2, you protect your team and keep your work safe.

Vibration Testing

Machines in atex zone 2 run for hours and shake a lot. Vibration testing checks if your rugged keyboards can keep working in these tough spots. Test labs use special machines to shake the keyboard in different ways. They mount the keyboard on a strong fixture and run it through many vibration patterns. These tests copy the real shaking you find in atex zone 2. If your rugged keyboards pass, you know they will not break or stop working when machines vibrate. This keeps your atex zone 2 site running without problems.

- Vibration testing uses electrodynamic shakers to copy real-world shaking.

- The keyboard is tested in both vertical and horizontal directions.

- Testers look for weak spots that could fail in atex zone 2.

MIL-STD-810H Certification

You want proof that your rugged keyboards can survive in atex zone 2. MIL-STD-810H is a military standard that tests rugged keyboards for shock, vibration, and more. This standard drops the keyboard many times from different heights and checks if it still works. It also tests for heat, cold, dust, and humidity. A rugged keyboard with MIL-STD-810H certification gives you confidence in atex zone 2. You know it can handle drops, shakes, and tough weather. This makes your rugged keyboards more trusted and valuable in atex and atex zone 2.

| Test Type | What It Checks For |

|---|---|

| Drop Testing | Survives falls in atex zone 2 |

| Vibration Testing | Works during constant shaking |

| Temperature Extremes | Handles hot and cold in atex zone 2 |

| Humidity Testing | Resists moisture in atex zone 2 |

| Dust and Sand | Keeps working in dirty atex environments |

Tip: Always look for MIL-STD-810H certification when picking rugged keyboards for atex zone 2. This ensures your keyboard will last and keep your team safe.

Temperature Tolerance: Operating Ranges for Hot & Cold Conditions

Wide Operating Temperature Range

If you pick a temperature-resistant industrial keyboard, it should work in both cold and hot places. Temperature tolerance is very important for durability. Some keypads face temperatures from -40°C to +85°C. They must keep working with no problems. Inside the keypad, materials get bigger or smaller as it gets hot or cold. If the design is not right, this can make cracks or stop the keys from working. Cold weather can make batteries run out faster. Hot weather can also make batteries not last as long. You need a keypad that works well in any weather.

Here is a table that shows the usual temperature ranges for different devices:

| Device Type | Typical Operating Temperature Range |

|---|---|

| Industrial PCs (general) | -20°C to 60°C (-4°F to 140°F) |

| Some Industrial PC models | -40°C to 70°C |

| Industrial Keypads & Related | Typically within the above PC ranges |

Keypads use strong materials like industrial silicone rubber and zinc alloy. These help the keypad last longer and stop damage from big temperature changes. Many keypads have certifications like NEMA 4X and UL60950. These show the keypad is safe and works well.

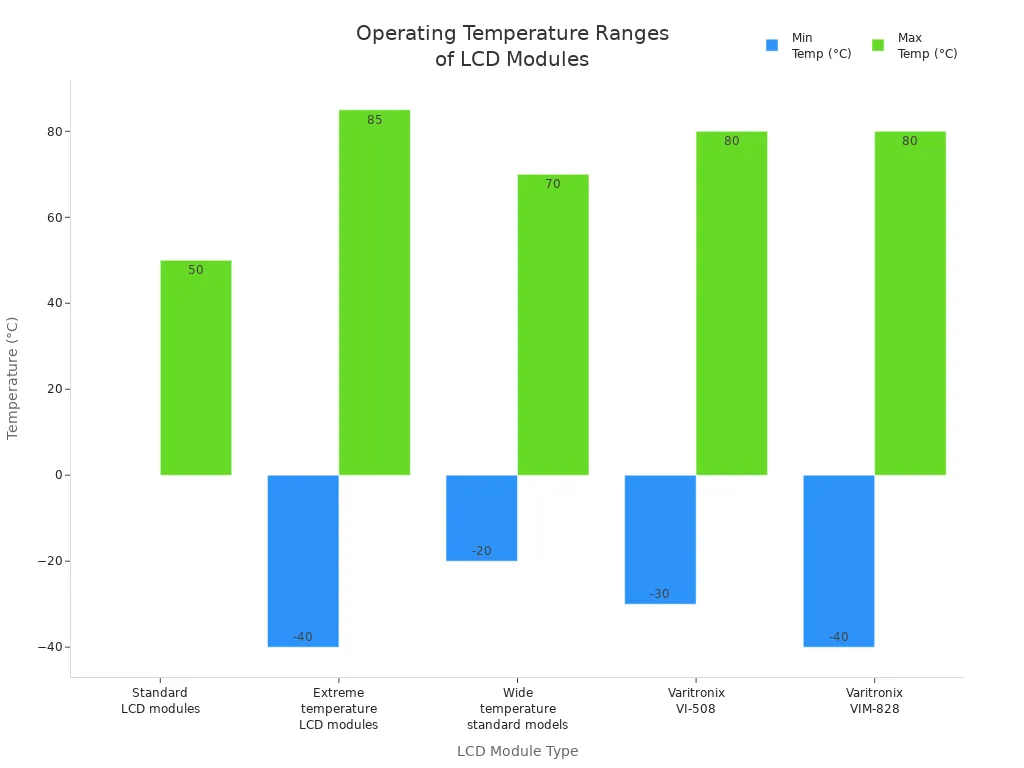

You can see how LCD modules are different in their temperature ranges:

Salt Spray Testing

Salt spray testing is also important for industrial keypads. This is needed if you use them near the ocean or in chemical plants. Salt and water can make metal parts rust and break. To check for corrosion resistance, makers use the Neutral Salt Spray (NSS) test. This test sprays salty water on the keypad for up to 48 hours at 35°C. The keypad should not have rust or damage after the test.

| Test Method | Test Solution Composition | Test Duration | Test Temperature | pH Value | Application Scope |

|---|---|---|---|---|---|

| NSS | 5% NaCl solution | 48 hours | 35°C | 6.5-7.2 | Metals, coatings |

Salt spray resistance helps your keypad last longer in tough places. It keeps the metal and electronic parts safe from rust. This means your keypad works longer and you do not have to replace it as often.

Tip: Always check the temperature and corrosion resistance needs before you buy a keypad for extreme places.

When you pick industrial keypads, look for strong durability and good certifications. These things help you get keypads that last a long time and work well.

- Choosing keypads with tough durability tests saves money on repairs and keeps people safe.

- Good keypads help your job go well, even in rough places.

- Certifications like UL, NEMA, and CE mean your keypad follows important safety and quality rules.

| Resource | What You Learn |

|---|---|

| UL Solutions | How keypads are tested and certified |

| BIFMA | Ways to test strength and durability |

If you want to know more, look at UL Solutions or BIFMA to learn about how keypads are tested for quality and strength.

FAQ

What does atex mean for industrial keypads?

You see atex on many industrial keypads. This means the keypad meets strict rules for safety in places with explosive gases or dust. You need atex keypads in atex zone 2. These keypads help you avoid accidents and keep your work safe.

Why do you need atex zone 2 keypads in harsh environments?

You need atex zone 2 keypads because these areas have dangerous gases or dust sometimes. Atex zone 2 keypads keep you safe. They stop sparks or heat from causing explosions. You must use atex keypads in atex zone 2 to follow safety laws.

How do you know if a keypad is safe for atex zone 2?

You check the label. It should say atex and show the atex zone 2 mark. You also look for test results. These show the keypad passed atex safety tests. Always pick a keypad with atex approval for atex zone 2.

What is the importance of atex compliance for your work?

Atex compliance keeps you safe in atex zone 2. You avoid fines and accidents. You protect your team and equipment. You also meet legal rules. The importance of atex compliance grows when you work in atex zone 2.

What should you look for when choosing the right atex zone 2 rugged keyboard?

You should check for atex approval, strong materials, and waterproof ratings. Make sure the keyboard works in atex zone 2. You want a keypad that lasts in tough places. Choosing the right atex zone 2 rugged keyboard helps you stay safe and follow the rules.

Tip: Always read the atex label before you buy a keypad for atex zone 2.

Post time: Aug-12-2025