You operate in environments where safety is not just a priority; it is a fundamental requirement. Effective communication prevents incidents in hazardous industrial environments. Standard communication devices spark explosions in volatile atmospheres. This creates immense danger. You need specialized solutions for operational integrity. An explosionproof telephone ensures clear, safe communication. These industrial telephones are vital for hazardous area communication. Specifically, an ATEX telephone provides certified safety in such zones. For example, in oil and gas communication systems, Explosion Proof Telephones are indispensable.

You operate in environments where safety is not just a priority; it is a fundamental requirement. Effective communication prevents incidents in hazardous industrial environments. Standard communication devices spark explosions in volatile atmospheres. This creates immense danger. You need specialized solutions for operational integrity. An explosionproof telephone ensures clear, safe communication. These industrial telephones are vital for hazardous area communication. Specifically, an ATEX telephone provides certified safety in such zones. For example, in oil and gas communication systems, Explosion Proof Telephones are indispensable.

Key Takeaways

- Explosion-proof telephones are vital for safety in dangerous industrial places. They stop sparks from causing fires.

- These special phones work in places with gas, dust, or chemicals. They keep workers safe.

- Explosion-proof phones have strong designs. They can handle tough conditions like water, dust, and heat.

- Look for ATEX, IECEx, or UL certifications. These show the phone meets high safety rules.

- Modern explosion-proof phones connect to different systems. They help with clear and fast communication.

Understanding Hazardous Environments and the Need for Explosion Proof Telephones

Defining High-Risk Industrial Zones

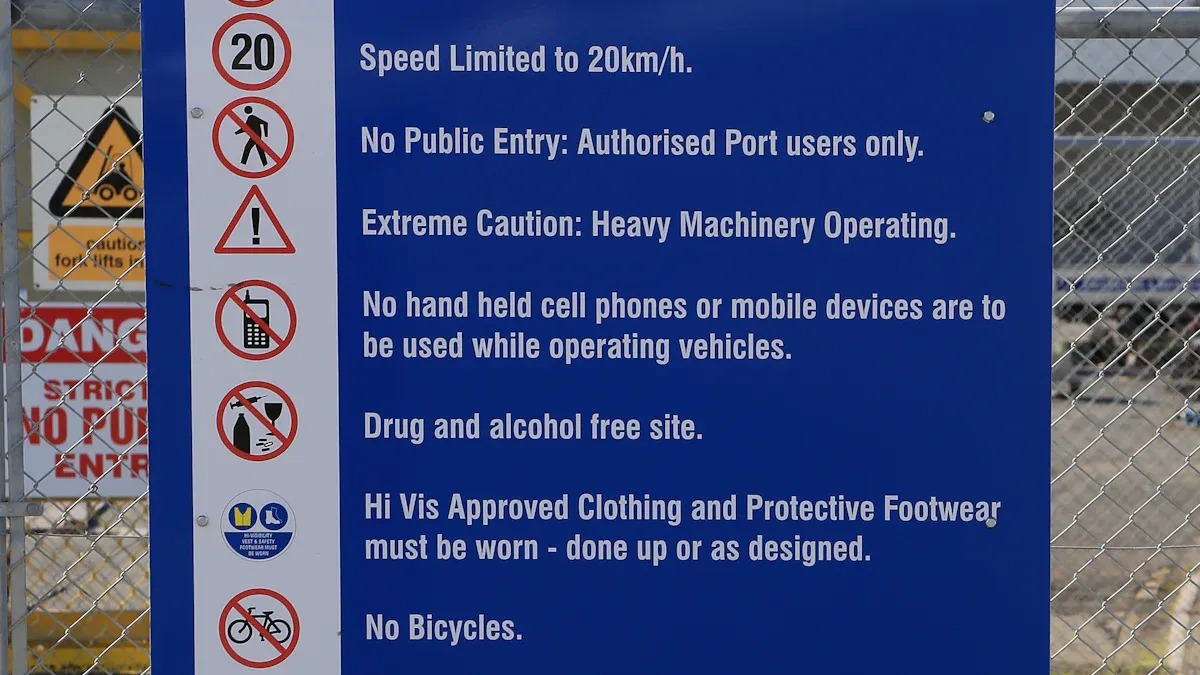

You operate in environments where explosive atmospheres pose constant threats. Industrial zones are classified as high-risk based on several critical factors. These include the likelihood and duration of explosive gases, vapors, or dusts. The specific type, quantity, and concentration of hazardous substances also determine the risk level. Furthermore, the frequency of an explosive atmosphere’s presence, the effectiveness of ventilation, and the control of potential ignition sources are all considered.

International standards like ATEX and IECEx guide these classifications. For example, IEC 60079-10-1:2015 defines gas and vapor hazardous areas:

- Zone 0: Explosive gas atmosphere is present continuously or for long periods. Think inside storage tanks.

- Zone 1: Explosive atmospheres are likely during normal operation. You find these near pumps or valves prone to leaks.

- Zone 2: Explosive gas atmospheres are unlikely in normal operation and persist only for short durations if they occur. Well-ventilated pump rooms often fall into this category.

Similarly, IEC 60079-10-2:2015 defines dust zones:

- Zone 20: Combustible dust clouds are present continuously or for long durations. Silos or dust collectors are prime examples.

- Zone 21: Explosive dust atmospheres are intermittently present during normal operation. Powder transfer stations fit this description.

Inherent Dangers of Standard Communication Devices

Using standard communication devices in these high-risk zones creates immense danger. They can become ignition sources. Common ignition sources include:

- Electrical Ignition Sources: Faulty wiring, overloaded circuits, or static electricity can spark. Damaged wires in industrial machines or electrical panels can ignite nearby dust or gas.

- Thermal Ignition Sources: Heat from hot surfaces, friction, or radiant heat poses a risk. Machinery with hot surfaces or processes generating high temperatures, like a furnace, can ignite flammable substances.

- Mechanical Ignition Sources: Sparks from metal impacts, grinding, or friction are dangerous. Welding operations produce sparks that can ignite surrounding materials.

- Chemical Ignition Sources: Spontaneous combustion and reactive materials are threats. Mixing incompatible chemicals can lead to spontaneous fires.

Non-certified devices are inherently dangerous. They also lead to legal non-compliance and regulatory penalties. You risk fines or operational shutdowns. Unreliable gear causes operational disruption. Workplace incidents, including explosions and injuries, become a real possibility. Furthermore, you may not qualify for insurance in hazardous work environments. Non-electrical equipment also poses an explosion risk through impact, friction, hot surfaces, and static electricity.

The Imperative for Specialized Explosion Proof Telephones

You need specialized communication solutions for these environments. Standard devices simply do not meet the safety requirements. Explosion Proof Telephones are specifically designed to prevent ignition. They contain potential sparks and heat within their robust casings. This design ensures safe operation even in the most volatile atmospheres. These specialized devices are not just a recommendation; they are a critical necessity for protecting your personnel and assets.

Key Features and Technological Advancements of Explosion Proof Telephones

Principles of Explosion Protection and Certification

You rely on specialized designs to prevent ignition in hazardous areas. Explosion Proof Telephones use fundamental principles to ensure safety. They contain any explosion that may originate within their housing. This prevents ignition of the surrounding atmosphere. Robust enclosures made of thick, heavy-duty materials achieve this containment. If internal combustion occurs, a flame path cools explosive gases. This quenches flames before they can exit the enclosure. Designers also minimize internal sparks. They carefully insulate and isolate potential ignition sources like switches and circuits. Temperature control is another vital principle. Materials remain below the ignition temperature of the surrounding atmosphere. This considers heat generated during normal operations. Advanced materials like high-strength aluminum alloys, stainless steel, and non-sparking materials provide durability, corrosion resistance, and effective heat dissipation. Innovative technologies include intrinsic safety barriers. These limit electrical energy. Flameproof enclosures contain internal explosions.

You can compare different safety approaches:

| Aspect | Explosion-Proof Phones | Intrinsically Safe Phones |

|---|---|---|

| Safety Principle | Contain any internal explosion with a strong enclosure | Limit energy so ignition cannot happen |

| Features | Heavy metal housing, explosion-proof hardware, flameproof seals, pressurization | Low-energy circuits, safety barriers, fail-safe parts |

| Application | Best for high-power devices or places with lots of flammable material | Best for low-power devices in areas with constant danger |

| Use Case | Mining, oil rigs, chemical plants (Zone 1 & 2) | Refineries, gas plants, areas with continuous risk (Zone 0 & 1) |

The phone uses special circuits to keep voltage and current very low. Safety barriers, like Zener barriers, stop too much energy from going to risky places. The phone has parts, like fuses, that shut it down safely if a problem occurs. The design keeps the phone from getting hot enough to start a fire. All parts, like batteries, must follow strict safety rules.

International certifications validate these safety measures. You need to look for these certifications.

- ATEX Certification (EU): This certification involves over 200 tests. It covers equipment explosion-proof performance and electromagnetic compatibility.

- IECEx Certification (International Electrotechnical Commission): This requires equipment to operate without faults for 1000 hours in explosive atmospheres.

- CB Certification: This covers essential indicators like electrical safety, temperature rise, and voltage withstand. Reports are recognized in 54 countries.

Other important certifications include:

- ATEX Explosion-Proof Camera Certification

- IECEx International Certification Scheme

- North American Hazardous Area Certification

These certifications ensure compliance with global safety, quality, and environmental requirements. For example, Joiwo products meet ATEX, CE, FCC, ROHS, and ISO9001 standards.

Robust Design and Durability for Extreme Conditions

You need telephones that withstand the harshest industrial environments. Explosion Proof Telephones are constructed with rugged materials. They feature reinforced enclosures and advanced insulation techniques. This minimizes electrical risks. They are dustproof, waterproof, and shock-resistant. This ensures reliable performance in extreme conditions. These conditions include heavy rain, high temperatures, or industrial vibration.

Manufacturers use specific materials and construction techniques for durability:

- Polycarbonate Materials: These are highly durable, impact-resistant, and withstand high temperatures. They offer excellent protective properties.

- Aluminum Enclosures: These are lightweight, corrosion-resistant, and possess excellent heat dissipation properties.

- Silicone Rubber: This material offers flexibility, high-temperature resistance, and superior sealing capabilities. It protects against dust, water, and other environmental factors.

Other advanced materials include:

- Corrosion-resistant aluminum alloy

- Specialized sealing

- Intrinsically safe components

- Stainless steel (for box and body)

- SMC (Sheet Molding Compound)

- Heavy metal

- Robust aluminum alloy die-cast body

These materials contribute to the phone’s ability to endure extreme conditions. Standards and ratings further guarantee durability. These include:

- IP66/IP68/IP69K for dust and water resistance

- IK10 for impact protection

- IEC 60079, ATEX, UL for legal and safety compliance

Advanced Communication Capabilities and Integration

Modern Explosion Proof Telephones offer more than just basic communication. They integrate advanced features for clear and reliable communication. You get crystal-clear audio performance even in high ambient noise levels. This includes environments exceeding 90 dB. Advanced digital noise suppression technology makes this possible. Many models also support VoIP SIP protocols. This provides flexible integration with various communication infrastructures.

These telephones integrate seamlessly with existing industrial control systems or emergency response networks.

- Analog Integration: Explosion Proof Telephones can connect directly to analog ports on PAGA (Public Address and General Alarm) systems. They can also use simple relays for alarm activation. This allows the PAGA system to detect phone usage and broadcast messages. The phone can also trigger alarms.

- VoIP/SIP Integration: Modern facilities use Voice over Internet Protocol (VoIP) or Session Initiation Protocol (SIP) for digital integration. Telephones with VoIP/SIP capabilities connect to the facility’s network. This enables automatic dialing, pre-recorded messages, call forwarding, and group calls during emergencies.

- Digital I/O Integration: This method uses simple on/off signals for direct system linking. An alarm system detecting a gas leak can send a digital signal to the PAGA system. This activates an evacuation message. A phone button can trigger a silent alarm in a control room.

- Protocol Converters and Gateways: These devices act as translators between systems that use different communication protocols. This includes an older analog PAGA system and a new digital alarm system. They ensure all safety infrastructure components communicate effectively.

- Centralized Control System Integration: The most advanced method involves a central system. This system monitors and coordinates all safety devices. This includes PAGA, alarm systems, and Explosion Proof Telephones. It manages responses, activates alarms, broadcasts messages, and logs communication. This provides a comprehensive overview and efficient emergency management.

Compliance with Global Safety Standards for Explosion Proof Telephones

You must ensure your communication equipment meets strict global safety standards. These standards guarantee the safe operation of devices in hazardous areas. Compliance protects your personnel and prevents catastrophic incidents. It also ensures legal adherence and avoids penalties. Several key certifications govern explosion-proof equipment worldwide.

The ATEX (Atmosphères Explosibles) certification is a European standard. It ensures electrical equipment is safe for use in explosive atmospheres. This certification is mandatory for devices in hazardous areas within the EU. The IECEx (International Electrotechnical Commission Explosive) certification is a globally recognized standard. It allows equipment use across different regions without additional approvals. UL (Underwriters Laboratories) certification is a North American safety standard. It verifies compliance with rigorous explosion-proof requirements through extensive testing. While an IP rating indicates resistance to dust and water, it does not alone guarantee flameproof properties. You should consider IP ratings in addition to ATEX, IECEx, or UL certifications.

Understanding the differences between these certifications helps you choose the right equipment. Here is a comparison of IECEx and ATEX certifications:

| Feature | IECEx Certification | ATEX Certification |

|---|---|---|

| Applicable Region | Global | European Union |

| Scope of Application | Explosive gas and dust environments globally | Primarily explosive environments in Europe |

| Temperature Classes | T1 to T6 | T1 to T6 |

| Gas Group Classification | IIC, IIB, IIA | IIC, IIB, IIA |

| Dust Group Classification | Dust groups such as Dc for combustible dust | Similar dust classification as IECEx |

| Zones/Category Classification | Zone 0, Zone 1, Zone 2 | Category 1, Category 2, Category 3 for varying risks |

| Device Types | Ex d, Ex e, Ex i, Ex n, Ex m | Ex d, Ex e, Ex i, Ex n, Ex m |

| Protection Level | Ex ic (Intrinsic Safety) – Low-energy, safe even in fault conditions | Category 1 – Used in areas where explosive atmospheres are present continuously |

| Safe Operation Temperature | -10°C to +55°C operational range | -10°C to +55°C operational range |

| Certification Labels | Requires IECEx label with all relevant certification information | Requires ATEX label with all relevant certification information |

These certifications ensure that Explosion Proof Telephones meet the highest safety benchmarks. They confirm the devices can operate reliably without becoming ignition sources. You gain confidence in your communication infrastructure. This compliance is essential for maintaining a safe and productive industrial environment.

Diverse Applications of Explosion Proof Telephones Across Industries

You find specialized communication solutions essential across many high-risk sectors. These devices ensure safety and operational continuity where standard equipment fails. They are not just tools; they are lifelines.

Oil, Gas, and Petrochemical Operations

You operate in environments where flammable gases and liquids are ever-present. Oil, gas, and petrochemical facilities demand the highest safety standards. Explosion Proof Telephones are indispensable in these settings. You deploy them in chemical and petrochemical plants, ensuring reliable communication. They are critical in oil refineries, where volatile substances are processed daily. These specialized phones function safely within the petrochemical industry and in areas with oil and gas atmospheres. They prevent ignition, protecting personnel and assets from catastrophic incidents.

Mining and Tunneling Environments

Mining and tunneling operations present unique and severe challenges for communication. You face harsh conditions daily. These include dust, moisture, and constant vibrations. Standard communication devices cannot withstand these elements. Explosion-proof phones are rugged and durable. They operate reliably in these demanding conditions. You also encounter potentially explosive gases, a significant hazard underground. These phones are intrinsically safe. They do not create sparks, preventing explosions. Wireless communication systems often fail due to interference or signal loss in underground settings. Explosion-proof phones offer unmatched reliability. They serve as an essential backup for constant communication.

Underground mines are often noisy. This makes clear communication difficult. These phones come equipped with loud speakers for clear audio. This ensures messages are heard. In critical situations, quick and reliable communication is vital. Explosion-proof phones are crucial for emergency communication. They enable rapid relay of urgent messages and coordination of evacuations. They withstand large temperature differences, high humidity, seawater, dust, corrosive atmospheres, explosive gases, particles, and mechanical wear and tear. They achieve an IP68 defend grade. They suit explosive gas atmospheres (Zone 1 and Zone 2), IIA, IIB, IIC explosive atmospheres, and dust zones (20, 21, 22). They also handle temperature classes T1 ~ T6. This ensures safety in hazardous areas. An aluminum alloy die-casting shell provides high mechanical strength and strong impact resistance. A heavy-duty handset and zinc alloy keypad add to their durability. A 25-30W loudspeaker and a 5W flash light/beacon make them highly visible and audible. The light flashes when ringing or in use. This attracts attention during calls in noisy environments.

Chemical and Pharmaceutical Manufacturing

Chemical and pharmaceutical manufacturing plants handle volatile substances and fine powders. These materials pose significant explosion risks. You integrate explosion-proof telephones into your safety protocols. They enable quick communication during emergencies and routine operations. Their ability to function reliably in hazardous zones helps prevent accidents. They coordinate responses and maintain operational continuity. In chemical plants, they ensure reliable communication without risk of ignition. This is vital where you handle volatile substances. In pharmaceutical manufacturing facilities, they maintain communication in areas with flammable solvents or powders. They adhere to strict safety standards. These devices improve safety outcomes. They streamline operations. They ensure compliance with safety regulations. Ultimately, they reduce the risk of catastrophic accidents. They prevent sparks or heat from igniting flammable gases, vapors, or dust. Compliance with strict safety standards (ATEX, IECEx, UL certifications) is a core feature. They withstand harsh conditions. These include extreme temperatures, humidity, and mechanical shocks. This ensures uninterrupted operation.

Marine, Offshore, and Other High-Risk Sectors

You face unique challenges in marine and offshore environments. These sectors include oil rigs, drilling platforms, and large vessels. You operate in conditions where saltwater corrosion, extreme weather, and constant vibration are common. Standard communication equipment quickly fails under such stress. You need robust, reliable communication systems to ensure safety and operational continuity.

Consider the specific demands of offshore platforms. You work with highly flammable materials like crude oil and natural gas. A single spark from a non-certified device can trigger a catastrophic explosion. You must have communication tools that prevent ignition. These tools must also withstand the harsh marine climate. They need to resist corrosion from salt spray and function reliably in high humidity.

Other high-risk sectors also depend on specialized communication.

- Wastewater Treatment Plants: You handle methane and other combustible gases. These gases are byproducts of organic decomposition. Communication devices must be intrinsically safe to prevent explosions.

- Power Generation Facilities: You often deal with coal dust or flammable fuels. These materials create hazardous atmospheres. You require communication systems that operate safely in these conditions.

- Aerospace Manufacturing: You use volatile chemicals and solvents in production processes. These substances demand explosion-proof equipment for worker safety.

- Defense and Military Installations: You operate in environments with potential for explosive materials or fuels. Secure and reliable communication is paramount.

In these diverse environments, you cannot compromise on safety. You need communication solutions that are not only durable but also certified for hazardous locations. These specialized devices ensure your teams can communicate effectively during routine operations and critical emergencies. They provide a vital link, protecting lives and assets in the most demanding industrial settings.

Market Dynamics and Future Trends for Explosion Proof Telephones

Global Market Growth and Driving Factors

You observe a significant expansion in the market for specialized communication devices. The global market for Explosion Proof VoIP Portable Phones was valued at $843.18 million in 2021. Experts project this market to grow to $2036.01 million by 2033, showing a robust CAGR of 7.623%. The broader Explosion-Proof Industrial Telephone Market also shows strong growth. It was valued at USD XX Billion in 2024 and will reach USD XX Billion by 2033. Furthermore, the global Explosion Proof Mobile Communication Market was valued at USD 2.1 billion in 2024. It is projected to reach USD 3.3 billion by 2030, growing at a CAGR of 7.6%. Explosion-Proof Mobile Phones are expected to hold 55% of this market share in 2024. You can expect a Compound Annual Growth Rate (CAGR) of 10.6% for the Explosion Proof Mobile Phone Market from 2025 to 2035.

Several factors drive this demand. Increasing safety regulations and industrial safety standards across hazardous sectors like oil and gas, mining, and chemical manufacturing play a crucial role. Rising infrastructure development in these sectors requires reliable communication devices. Technological advancements in explosion-proof communication equipment offer improved durability, clarity, and connectivity. Government initiatives promoting safety and environmental protection also contribute. The expansion of industrial zones and urbanization, along with a growing emphasis on worker safety, further fuels market growth.

Innovations in Explosion Proof Telephones Technology

You see continuous innovation in explosion-proof communication technology. Manufacturers develop new materials to withstand extreme conditions while maintaining device functionality. Improved battery technology offers longer life and faster charging without compromising safety. Enhanced connectivity, including 5G and beyond, provides faster, more reliable connections in challenging environments. Research into more resistant designs uses advanced materials and innovative techniques. You also find more intuitive user interfaces for easier use in difficult conditions. Integration with other intrinsically safe devices creates a comprehensive safety ecosystem.

Wireless and VoIP integration enables flexible deployment, reduces cabling costs, and facilitates real-time collaboration. IoT and remote monitoring allow for remote diagnostics, real-time status updates, and predictive maintenance. This improves safety management and reduces downtime. Enhanced durability and material science utilize advanced materials like corrosion-resistant alloys and impact-proof plastics. This extends device lifespan in harsh environments. Smart safety features incorporate emergency alarms, automatic fault detection, and environmental sensors for rapid incident response. Energy efficiency and power management innovations extend device operation in remote locations. For example, Nokia collaborated with i.safe MOBILE in September 2023. They released ruggedized 5G handheld devices for private networks in hazardous industrial environments. Betavolt, a Chinese startup, introduced a revolutionary battery in January 2024. It powers smartphones for approximately 50 years without recharging.

Regulatory Landscape and Compliance Challenges

You navigate a complex regulatory landscape for explosion-proof equipment. Primary regulatory bodies include OSHA (Occupational Safety and Health Administration), NFPA (National Fire Protection Association), and NEC (National Electrical Code). The EPA (Environmental Protection Agency) also influences these standards.

The landscape of safety standards and compliance is continually evolving, driven by technological advancements and lessons learned from past incidents. As such, companies must remain vigilant and proactive in updating their safety protocols and equipment. This involves regular training for personnel, routine maintenance of devices, and staying informed about the latest developments in safety standards.

You face challenges in achieving compliance with these evolving international safety standards. Staying informed about new regulations and ensuring your equipment meets the latest certifications requires ongoing effort. You must also manage the costs associated with compliance and certification processes.

Strategic Partnerships and Industry Leadership

You see a dynamic landscape in the explosion-proof communication sector. Strategic partnerships and strong industry leadership drive innovation and market growth. Several companies stand out as market leaders. Pixavi offers innovative communication solutions for extreme conditions. JFE Engineering provides tailored solutions for hazardous environments. Extronics develops rugged mobile devices with a focus on industrial mobility. Ecom instruments offers a comprehensive range of certified mobile phones, especially for oil and gas. Pepperl+Fuchs leads in explosion protection, providing reliable mobile technology. Sonim Technologies is known for durable devices in challenging conditions. Airacom RTLS blends technology and safety with real-time location services. Bartec specializes in mobile communication solutions adhering to strict safety regulations. i.safe MOBILE focuses on state-of-the-art technology and compliance. TR Electronic develops unique solutions for mobile applications in hazardous zones. Kenwood integrates safety features into mobile solutions. Panasonic offers robust mobile devices for extreme environments.

Aegex Technologies, LLC holds the largest share in sales revenue within the global explosion-proof mobile communication devices market. You also find other significant players like Xciel Inc., Kyocera Corporation, and RugGear.

Manufacturers and technology providers form strategic partnerships to enhance their offerings. You see collaborations between traditional explosion-proof equipment manufacturers and technology firms. These partnerships develop hybrid solutions. They combine certified hardware with advanced software interfaces. Companies also form strategic alliances and mergers. These actions augment technological capabilities and help penetrate new markets. Partnerships with technology providers are crucial for incorporating 5G and cloud-based solutions. This enables real-time data transmission and remote management. These collaborations ensure you receive the most advanced and safest communication tools available.

You now understand the critical role Explosion Proof Telephones play. They are indispensable for safety in hazardous industrial environments. These specialized devices ensure clear communication, boosting operational efficiency and significantly mitigating risks. As technology advances, you can expect even more integrated and intelligent communication solutions for your high-risk zones.

FAQ

What makes a telephone “explosion-proof”?

You design explosion-proof telephones to prevent ignition in hazardous areas. They contain any internal sparks or explosions within a robust casing. This stops flames from reaching the surrounding volatile atmosphere. They use specialized materials and circuits for safety.

Where do you typically use explosion-proof telephones?

You use these phones in high-risk industrial zones. These include oil and gas refineries, chemical plants, mining operations, and offshore platforms. They ensure safe communication where flammable gases, vapors, or dusts are present.

What certifications should you look for in an explosion-proof telephone?

You should look for international certifications like ATEX, IECEx, and UL. These certifications confirm the device meets strict safety standards. They ensure the phone operates safely in explosive atmospheres.

Can explosion-proof telephones integrate with your existing communication systems?

Yes, they can. Modern explosion-proof telephones offer advanced integration capabilities. They support VoIP SIP protocols for digital networks. They also connect to analog systems. This allows seamless communication within your facility’s infrastructure.

How do explosion-proof telephones withstand harsh industrial conditions?

Manufacturers build these phones with robust materials. They use reinforced enclosures and advanced insulation. This makes them dustproof, waterproof, and shock-resistant. They operate reliably in extreme temperatures, high humidity, and corrosive environments.

Post time: Jan-26-2026