In hazardous environments, ATEX telephones play a critical role in ensuring safety. These explosionproof telephones are designed to function reliably in areas where flammable gases and vapors may be present. The need for a hazardous area industrial telephone is paramount as it allows for clear communication during emergencies. Compliance with ATEX certification EN60079 guarantees that equipment meets strict safety standards. The Ex marking Ex d IIC T6 telephone indicates suitability for use in explosive atmospheres, further enhancing workplace safety.

Key Takeaways

- ATEX telephones enhance safety by preventing ignition in explosive environments, significantly reducing accident risks.

- Compliance with ATEX certification ensures that telephones meet strict safety standards, protecting workers in hazardous areas.

- These devices improve emergency response times, allowing for quick communication during critical situations, which can save lives.

- ATEX telephones are built for durability, ensuring reliable operation even in harsh conditions, which boosts overall operational efficiency.

- Integrating ATEX telephones with existing safety systems enhances communication and coordination, further improving safety protocols.

Understanding ATEX Telephones

ATEX telephones are specialized communication devices designed for use in hazardous environments, particularly in the oil and gas sector. These telephones meet strict safety standards to prevent ignition in explosive atmospheres. Understanding their features and functionalities is crucial for ensuring safety in these high-risk areas.

Key Features of ATEX Telephones

The following table outlines the main technical features that distinguish ATEX telephones from standard telephones:

| Feature | Description |

|---|---|

| Certification Scope | Must meet ATEX (EU) and/or IECEx (global) standards, with specific gas group and temperature ratings. |

| Protection Rating | Should have IP68 or IP69K for dust and water resistance, essential for harsh environments. |

| Battery Safety | Batteries must be intrinsically safe and tested under fault conditions to ensure safety. |

| Connectivity | Support for modern connectivity options like 4G LTE, Wi-Fi 6, and Bluetooth 5.x for reliable data transfer. |

| Display Usability | Features like glove-mode screens and anti-reflective coatings are important for outdoor usability. |

| Software & Updates | Long-term OS support and security updates are crucial for enterprise use. |

| Mounting & Accessories | Compatibility with various accessories enhances usability in operational settings. |

ATEX telephones function differently from non-ATEX devices, especially in explosive atmospheres. The following table compares their features:

| Feature | ATEX Telephones | Non-ATEX Devices |

|---|---|---|

| Certification | Must be ATEX certified for safety | No specific certification required |

| Protective Features | Flameproof enclosures, strong cases | Standard materials, no explosion protection |

| Operational Requirements | Must meet Directive 2014/34/EU | No specific operational requirements |

| Risk Management | Designed to prevent ignition in explosive atmospheres | Higher risk of ignition in hazardous areas |

| Compliance | Legal requirement in EU | No legal compliance needed |

Importance of Certification Levels

ATEX telephones come with various certification levels, ensuring they can operate safely in different environments. The following table summarizes the different ATEX certification levels for telephones used in oil and gas environments:

| Classification Type | Group | Description |

|---|---|---|

| Gas Groups | IIC | Acetylene and hydrogen group, most easily ignited. |

| Gas Groups | IIB | Ethylene group. |

| Gas Groups | IIA | Propane group (oil & gas). |

| Dust Groups | IIIC | Conductive dust. |

| Dust Groups | IIIB | Non-conductive dust. |

| Dust Groups | IIIA | Combustible flyings. |

| Temperature Classes | T1 | 450°C maximum surface temperature. |

| Temperature Classes | T2 | 300°C maximum surface temperature. |

| Temperature Classes | T3 | 200°C maximum surface temperature. |

| Temperature Classes | T4 | 135°C maximum surface temperature. |

| Temperature Classes | T5 | 100°C maximum surface temperature. |

| Temperature Classes | T6 | 85°C maximum surface temperature. |

| Equipment Protection Levels | Ga | Highest protection, safe even with two simultaneous faults. |

| Equipment Protection Levels | Gb | High protection, safe during normal operation and single fault. |

| Equipment Protection Levels | Gc | Basic protection, safe during normal operation. |

| Equipment Protection Levels | Ex Da | Highest protection for dust, safe even with two simultaneous faults. |

| Equipment Protection Levels | Ex Db | High protection for dust, safe during normal operation and single fault. |

| Equipment Protection Levels | Ex Dc | Basic protection for dust in normal conditions. |

ATEX telephones integrate seamlessly with other safety technologies in oil and gas facilities. They comply with various standards, ensuring compatibility across regions. These devices support standardized interfaces, allowing for easy integration with existing systems. Remote management capabilities enhance maintenance efficiency, while interoperability with alarm systems and control panels improves overall safety protocols.

Safety Needs in the Oil and Gas Sector

The oil and gas sector presents unique safety challenges due to its hazardous environments. Workers often face explosive atmospheres, which can arise from flammable gases and combustible dust. Understanding these hazards is crucial for implementing effective safety measures.

The following table outlines common zones in oil and gas facilities where ATEX-certified communication devices are essential:

| Zone | Description |

|---|---|

| Zone 0 | An area with an explosive atmosphere continuously or for long periods. |

| Zone 1 | An area where an explosive atmosphere is likely to occur occasionally. |

| Zone 2 | An area where an explosive atmosphere is not likely to occur during normal operation. |

| Zone 20 | An area with ignitable concentrations of combustible dust present continuously. |

| Zone 21 | An area where ignitable concentrations of combustible dust are likely to occur occasionally. |

| Zone 22 | An area where ignitable concentrations of combustible dust are not likely to occur under normal conditions. |

ATEX telephones address these safety needs effectively. They comply with strict safety standards, preventing explosions in hazardous environments. These devices enhance operational efficiency and emergency response through robust communication features. Additionally, modern ATEX telephones integrate seamlessly into existing safety systems, supporting various communication protocols, including VoIP.

Installation of ATEX telephones presents challenges that require careful consideration. Qualified personnel must handle the installation to ensure compliance with safety protocols. Proper installation procedures, including correct grounding and bonding, are essential to prevent ignition. Environmental factors, such as temperature and humidity, also play a significant role in the installation process.

To minimize ignition risks, operators should:

- Use ATEX-certified equipment.

- Implement intrinsically safe design principles.

- Conduct thorough system testing post-installation.

By addressing these safety needs, ATEX telephones contribute significantly to overall risk management strategies in oil and gas operations. Reliable communication tools enhance collaboration and operational efficiency, which are critical for maintaining safety in this high-risk industry.

Benefits of Using ATEX Telephones

ATEX telephones offer numerous advantages that enhance safety and operational efficiency in the oil and gas sector. These specialized devices are designed to function reliably in hazardous environments, ensuring that communication remains uninterrupted even in the most challenging conditions. Here are some key benefits of using ATEX telephones:

- Enhanced Safety: ATEX telephones significantly reduce the risk of ignition in explosive atmospheres. Their design prevents sparks and heat generation, which are critical in environments where flammable gases and vapors are present. A major oil and gas company reported a significant reduction in incidents related to mobile device use in hazardous areas after implementing intrinsically safe phone cases. This implementation not only improved safety but also resulted in substantial cost savings.

- Improved Emergency Response: In emergencies, every second counts. ATEX telephones improve emergency response times in hazardous oil and gas environments. For instance, during an incident at an offshore platform, the use of explosion-proof telephones improved emergency response times by up to 30%. Workers could quickly alert safety teams without risking ignition, leading to faster evacuations and effective hazard mitigation.

- Long-Term Operational Reliability: These telephones are built to withstand demanding conditions. They ensure continuous operation, even in potentially dangerous settings. ATEX telephones feature advanced communication capabilities that enhance operational efficiency and improve emergency response. Their integration into existing facility systems contributes to overall safety and compliance in hazardous environments.

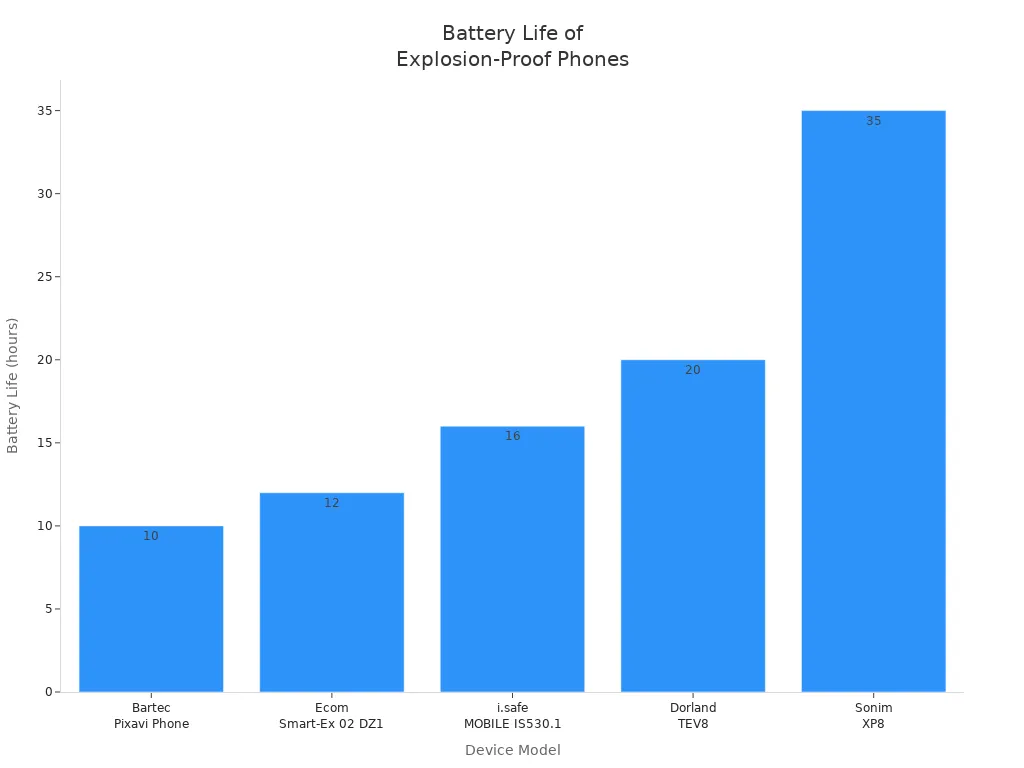

- Superior Performance: When compared to other explosion-proof communication devices, ATEX telephones often outperform in several areas. The following table illustrates the battery life of various models:

| Model | Battery Life |

|---|---|

| Bartec Pixavi Phone | Up to 10 hours |

| Ecom Smart-Ex 02 DZ1 | Up to 12 hours |

| i.safe MOBILE IS530.1 | Up to 16 hours |

| Dorland TEV8 | Up to 20 hours |

| Sonim XP8 | Up to 35 hours |

- Clear Communication: Audio clarity is vital for safety in hazardous environments. ATEX telephones ensure clear communication, which is essential for effective coordination among teams. Additionally, features like Active Noise Cancellation (ANC) technology improve focus and reduce background noise, further enhancing communication quality.

Real-World Case Studies

Numerous real-world case studies demonstrate the effectiveness of ATEX telephones in enhancing safety within the oil and gas sector. These documented instances highlight how these specialized devices prevent major accidents and improve operational efficiency.

- A major oil and gas company improved communication and productivity in offshore operations by using ATEX telephones. The implementation of Ex-Proof mobile phones led to streamlined workflows and better coordination in potentially explosive environments.

- The rugged design of these devices allowed them to endure harsh offshore conditions, contributing significantly to safety. Workers reported fewer communication breakdowns during critical operations, which reduced the risk of accidents.

Another notable case involved an offshore drilling platform where ATEX telephones played a vital role during an emergency. When a gas leak occurred, workers quickly used the devices to alert safety teams. The rapid communication enabled a swift evacuation, minimizing potential harm to personnel.

In a different scenario, a refinery adopted ATEX telephones to enhance communication among teams working in hazardous zones. The result was a marked improvement in response times during routine maintenance and emergency situations. The devices facilitated clear communication, allowing teams to coordinate effectively and address issues promptly.

These case studies illustrate the importance of ATEX telephones in maintaining safety in oil and gas operations. Their ability to function reliably in hazardous environments makes them indispensable tools for effective communication and emergency response.

Regulatory Compliance and Standards

Regulatory compliance is crucial for the safe operation of ATEX telephones in the oil and gas industry. These devices must meet specific standards to ensure safety in explosive environments. The following table outlines key certification types relevant to ATEX telephones:

| Certification Type | Description |

|---|---|

| ATEX Certification | Ensures electrical equipment is safe for use in explosive atmospheres, mandatory in the EU for hazardous areas. |

| IECEx Certification | A globally recognized standard for explosion-proof equipment, ensuring compliance with international safety regulations. |

| UL Certification | A North American safety standard verifying compliance with explosion-proof requirements. |

| IP Rating | Indicates resistance to dust and water, crucial for durability in extreme environments. Must be checked alongside ATEX/IECEx/UL certifications. |

In Europe, ATEX certification is mandatory for equipment used in explosive atmospheres. In contrast, North America requires UL certification for similar devices. The certification processes differ significantly. ATEX requires a comprehensive technical dossier, while UL necessitates detailed test reports and safety data.

Non-compliance with these regulations can lead to severe consequences. Companies may face significant penalties, including hefty fines imposed by regulatory bodies. Legal liability can arise from accidents, leading to lawsuits for damages and injuries. For instance, in 2018, a major oil and gas company was fined $2.5 million for failing to comply with safety regulations. This case highlights the financial risks associated with non-compliance.

Moreover, the 2010 Deepwater Horizon oil spill resulted in BP facing over $65 billion in fines and settlements due to violations of safety regulations. Such incidents underscore the severe legal implications of non-compliance. Companies that do not adhere to safety standards risk damaging their reputation, which can lead to a loss of business.

ATEX telephones play a vital role in ensuring safety in the oil and gas industry. Their design significantly reduces explosion risks in hazardous environments by meeting stringent safety standards. The benefits of adopting ATEX telephones include:

- Enhanced safety for workers in explosive atmospheres.

- Compliance with mandatory regulations, ensuring adherence to EU safety standards.

- Improved operational efficiency, leading to increased productivity.

The ATEX Compliance Upgrades for Refineries market is projected to grow significantly, indicating a strong alignment with safety initiatives. Companies should prioritize the adoption of ATEX telephones to enhance safety protocols and protect their workforce.

FAQ

What are ATEX telephones?

ATEX telephones are specialized communication devices designed for use in hazardous environments. They meet strict safety standards to prevent ignition in explosive atmospheres, ensuring safe communication in oil and gas operations.

Why is ATEX certification important?

ATEX certification ensures that equipment can safely operate in explosive atmospheres. It verifies compliance with safety standards, reducing the risk of accidents and enhancing worker safety in hazardous environments.

How do ATEX telephones improve safety?

ATEX telephones prevent ignition risks in explosive areas. Their robust design and features, such as clear audio and emergency alerts, enhance communication, ensuring quick responses during emergencies.

Can ATEX telephones integrate with existing systems?

Yes, ATEX telephones can integrate seamlessly with existing safety systems. They support various communication protocols, allowing for easy incorporation into current operational frameworks in oil and gas facilities.

What maintenance is required for ATEX telephones?

Regular maintenance includes checking for physical damage, ensuring battery functionality, and verifying compliance with safety standards. Routine inspections help maintain operational reliability and safety in hazardous environments.

Post time: Feb-03-2026