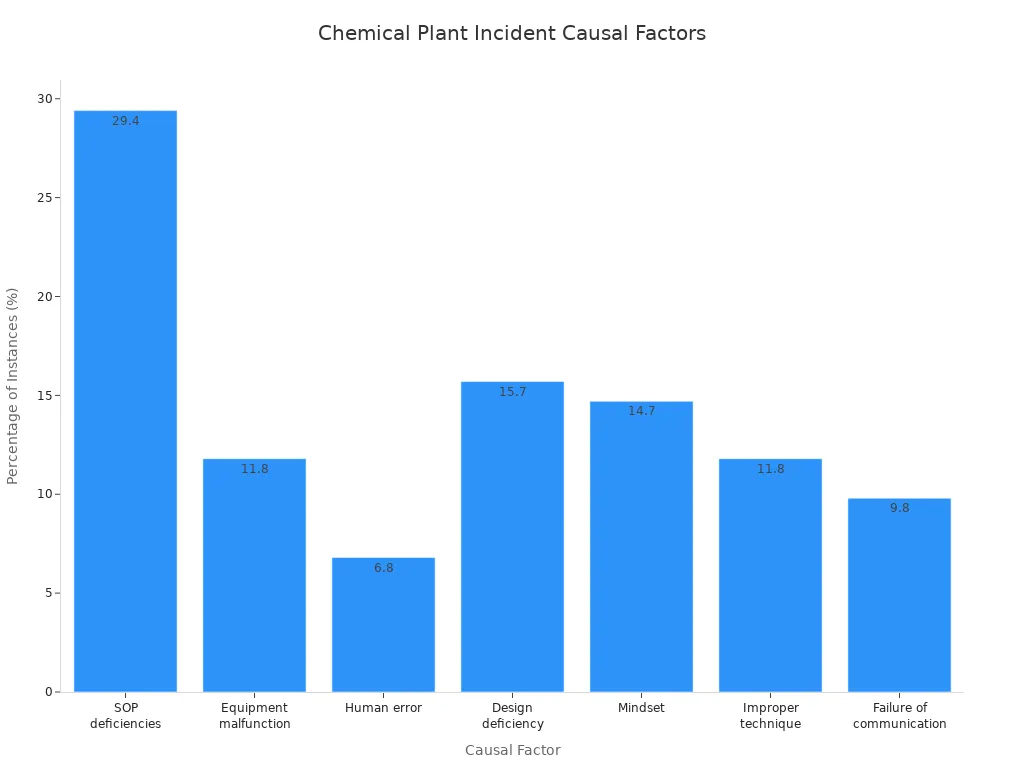

Chemical plants require robust communication systems for safety and daily operations. A compliant PA System Server plays a critical role in emergency response. Designing a future-proof system for 2026 presents significant challenges. Reliable communication prevents incidents. Data from 2002 shows communication failures account for 9.8% of chemical plant incidents. This emphasizes the need for effective systems.

Ensuring safety in evolving regulatory landscapes is paramount.

Key Takeaways

- Chemical plants need strong PA systems for safety. These systems help during emergencies. Communication failures cause many plant incidents.

- PA systems must follow rules from groups like OSHA and NFPA. These rules make sure the systems are safe. New rules will cover cyber security and smart technology.

- Design PA systems for dangerous areas. Use special enclosures to protect equipment. These enclosures keep out flammable materials and bad weather.

- A good PA system needs backup parts. This keeps it working if one part fails. It also needs strong processors and storage for data.

- Manage the PA system over time. Test it often. Fix problems before they get big. Plan for disasters to keep communication working.

Navigating Compliance for PA System Servers by 2026

Compliance forms the bedrock for any critical infrastructure within chemical plants. For Public Address (PA) systems, adherence to stringent regulations ensures operational safety and effectiveness, especially during emergencies. Plant operators must understand the evolving landscape of standards and legal requirements. This understanding helps them design and implement a compliant PA System Server by 2026.

Key Regulatory Bodies and Standards for PA System Servers

Several regulatory bodies and industry standards govern PA systems in hazardous environments. These entities establish guidelines for equipment design, installation, and operation. They aim to protect workers and the surrounding community.

- Occupational Safety and Health Administration (OSHA): OSHA sets workplace safety standards in the United States. Its regulations often dictate requirements for emergency communication systems, including audible alarms and clear voice messages. Employers must provide a safe working environment.

- National Fire Protection Association (NFPA): NFPA develops codes and standards for fire safety. NFPA 72, the National Fire Alarm and Signaling Code, includes provisions for emergency communication systems. These provisions cover mass notification systems, which are crucial for chemical plants.

- International Electrotechnical Commission (IEC): The IEC publishes international standards for electrical, electronic, and related technologies. IEC 60079 series, for example, addresses equipment for explosive atmospheres. This standard directly impacts the design and certification of components within a PA System Server located in hazardous zones.

- American National Standards Institute (ANSI): ANSI coordinates the development of voluntary consensus standards in the U.S. Many industry-specific standards, including those for industrial control systems, carry ANSI accreditation.

These bodies ensure PA systems meet minimum safety and performance criteria. They provide a framework for reliable emergency communication.

Anticipated Updates Affecting PA System Servers

Regulatory landscapes are dynamic; they continuously evolve to address new technologies and emerging risks. By 2026, several updates could impact PA System Servers in chemical plants.

- Enhanced Cybersecurity Requirements: Governments and industry groups increasingly focus on cybersecurity for critical infrastructure. New regulations will likely mandate more robust security protocols for network-connected PA systems. These protocols will protect against cyber threats that could disable communication during an emergency.

- Integration with IoT and AI: The integration of Internet of Things (IoT) devices and Artificial Intelligence (AI) in plant operations is growing. Future standards may require PA systems to integrate seamlessly with these technologies. This integration could enable more intelligent and automated emergency responses. For example, AI could trigger specific PA announcements based on real-time sensor data.

- Stricter Environmental Resilience Standards: Climate change concerns drive demand for more resilient infrastructure. Future standards might impose stricter requirements for PA system components. These components must withstand extreme weather conditions, such as floods, high temperatures, or seismic activity.

- Updated Hazardous Area Classifications: As understanding of hazardous materials improves, classification zones may change. These changes could affect where plants can place PA system components and what type of enclosures they require.

Plant operators must monitor these anticipated changes. Proactive planning ensures continued compliance and avoids costly retrofits.

Documentation and Certification for PA System Servers

Thorough documentation and proper certification are essential for demonstrating compliance. They provide proof that a PA system meets all applicable standards and regulations.

- Design Specifications: Comprehensive design documents detail every aspect of the PA system. These include architectural diagrams, component lists, and wiring schematics. They show how the system meets performance and safety requirements.

- Hazardous Area Certifications: All equipment intended for hazardous locations must carry appropriate certifications. Examples include ATEX (Europe) or UL (North America) certifications. These certifications confirm the equipment’s suitability for use in explosive atmospheres.

- Software Validation Reports: For systems with complex software, validation reports are crucial. These reports demonstrate that the software performs as intended and meets security standards. They also confirm its reliability in critical situations.

- Installation and Commissioning Records: Detailed records of installation procedures and commissioning tests are necessary. These documents verify that qualified personnel installed and configured the system correctly. They also confirm the system operates according to specifications.

- Maintenance Logs: Ongoing maintenance logs track all inspections, repairs, and upgrades. These logs prove the system remains in good working order throughout its lifecycle. They also help identify potential issues before they become critical.

Maintaining meticulous documentation simplifies audits and ensures accountability. Certification provides external validation of the system’s compliance and safety.

Designing the PA System Server for Hazardous Areas

Designing a PA System Server for a chemical plant demands careful consideration of the environment. These facilities often contain hazardous areas. Engineers must ensure the server’s physical design protects it from potential hazards. This protection guarantees reliable operation and prevents ignition sources.

Hazardous Zone Classification for PA System Server Placement

Chemical plants contain areas with flammable substances. These areas require specific classifications to manage risks. Hazardous location classified areas contain flammable gas, liquids, or vapors. They also include combustible dusts or easily ignitable fibers and flyings. These substances, when combined with an oxidizer and an ignition source, can lead to an explosion or fire. Therefore, engineers must correctly identify these zones. This identification dictates the type of equipment suitable for installation.

Different classification systems exist. In North America, the National Electrical Code (NEC) uses Classes, Divisions, and Groups. Class I refers to flammable gases or vapors. Division 1 indicates hazardous substances are present continuously or intermittently. Division 2 means hazardous substances are present only under abnormal conditions. Globally, the International Electrotechnical Commission (IEC) uses Zones. Zone 0, 1, and 2 for gases and vapors, and Zone 20, 21, and 22 for dusts. Zone 1 corresponds roughly to Division 1, and Zone 2 to Division 2. Correctly classifying these zones is the first step. It ensures the PA System Server and its components meet the necessary safety standards for their specific location.

Enclosure Requirements for PA System Servers

Enclosures play a critical role in protecting electronic equipment in hazardous areas. They prevent flammable substances from contacting electrical components. For ATEX and IECEx Zone rated applications, purge systems are designated pz, py, and px. These systems maintain a safe internal environment. The recommended enclosure for purge and pressurization applications should have a minimum rating of NEMA Type 4 (IP65). This rating ensures the enclosure withstands purge testing and the harsh environment.

Purge systems work by introducing clean air or inert gas into the enclosure. This process removes any hazardous gases or dusts. After purging, pressurization maintains a safe space. It keeps internal pressure slightly above ambient, typically 0.1 to 0.5 inches of water column or 0.25 to 1.25 mbar. This positive pressure prevents hazardous material infiltration. Safety alarms and electrical lockout systems monitor pressurization. They ensure safe operation. The location of the pressure sensor is critical. It prevents false alarms, especially with internal components like servers that have fans creating varying pressure zones.

Consider the permissible operating temperature of internal equipment. Supplemental cooling or air conditioning may be necessary. This applies if heat generation exceeds dissipation or ambient temperatures are high. Any air conditioner used must be rated for operation in the hazardous area. It must also meet purge and pressurization requirements. This includes a barrier between the safe enclosure interior and the combustible atmosphere.

Different purge system types cater to various hazardous area classifications:

| Purge System Type | Area Classification | Equipment Type Installed |

|---|---|---|

| Z | Division 2 | Non-hazardous rated equipment |

| Y | Division 1 | Division 2 rated hazardous area equipment |

| X | Division 1 | Non-hazardous rated equipment |

NEMA 4X enclosures are highly recommended for chemical industry applications. They offer watertight protection against hose-directed water and splashing. They also provide corrosion resistance, typically through stainless steel construction. IP66 is generally equivalent to NEMA 4 and NEMA 4X in European and Asian markets. It provides protection against strong jets of water and dust. NEMA 4X specifically adds corrosion resistance to this level of protection. Chemical plants, coastal installations, and food processing facilities require corrosion-resistant materials. These include stainless steel or galvanized steel, or protective coatings designed to withstand specific chemicals. NEMA 4X offers the same protection as NEMA 4 but includes additional resistance to corrosion. It is a common choice for environments requiring wash-down and outdoor use. Plastic enclosures with this rating are widely available at a reasonable cost.

Environmental Considerations for PA System Servers

Beyond hazardous atmospheres, chemical plants present other environmental challenges. Temperature extremes, humidity, and vibration can impact equipment longevity. Enclosures must protect the PA System Server from these factors. Stainless steel enclosures are frequently utilized in chemical plants. They offer exceptional corrosion resistance, hygienic properties, and durability. These enclosures withstand aggressive environments and frequent wash-downs. This makes them ideal for specialized applications where such conditions are prevalent.

High humidity can lead to condensation, causing electrical shorts or corrosion. Enclosures must prevent moisture ingress. They often include heaters or desiccants to manage internal humidity. Vibration from heavy machinery can also damage sensitive electronic components. Mounting solutions and internal dampening systems mitigate these effects. Dust and particulate matter, even if not combustible, can accumulate. This accumulation leads to overheating or component failure. Enclosures must provide adequate sealing to keep these contaminants out. Proper environmental design ensures the PA System Server operates reliably under all plant conditions.

Core Architecture of a Robust PA System Server

A robust PA System Server forms the backbone of critical communication in chemical plants. Its core architecture must guarantee reliability, performance, and data integrity. Engineers design these systems to operate flawlessly, even under challenging conditions.

Redundancy and High Availability for PA System Servers

Continuous operation is paramount for a PA System Server. Redundancy and high availability (HA) strategies prevent communication failures. Implementing failover mechanisms ensures the system remains operational. Teams monitor critical components like FPGAs and CPUs. This monitoring triggers failover if a component fails. For instance, in PA-7000 Series firewalls within an HA cluster, a session distribution device detects Network Processing Card (NPC) failures. It then redirects session load to other cluster members.

Organizations must identify critical system components, such as authentication services or databases. They implement redundancy at different layers, using multiple web servers or service instances. Load balancers distribute traffic across these redundant servers. They also remove unhealthy servers from rotation. Database replication strategies, like primary-replica with automatic failover, ensure data availability. Regular testing of failover mechanisms confirms their functionality.

| Strategy | Description |

|---|---|

| Redundancy | Duplicates critical components to provide backup. |

| Failover | Automatically switches to a standby system upon primary system failure. |

| Load Balancing | Distributes network traffic across multiple servers to optimize resource use and prevent overload. |

| Replication | Creates and maintains multiple copies of data to enhance availability and disaster recovery. |

Processor and Memory for PA System Server Performance

The PA System Server requires sufficient processing power and memory to handle real-time audio and data. A powerful processor ensures quick response times for announcements and system commands. For optimal performance, an Intel Core i5, i7, or AMD equivalent processor is suitable. Adequate memory capacity supports simultaneous operations and prevents bottlenecks. Systems typically require 4GB DDR3 RAM or higher. This memory supports the operating system and application demands. A 64-bit system type is also standard.

Storage Solutions for PA System Server Data Integrity

Data integrity is crucial for a PA System Server. Reliable storage solutions protect critical information and ensure rapid access. Redundant Array of Independent Disks (RAID) is a common storage protocol. It enhances performance and reliability by combining several hard drives into a single unit. RAID ensures data integrity and availability. It mirrors or stripes data across multiple drives. This means if one drive fails, the information remains secure. SSD RAID (solid-state drive RAID) protects data by distributing redundant data blocks across multiple SSDs. While traditional RAID improved performance, SSD RAID primarily focuses on protecting data integrity if an SSD drive fails.

Power Supply and UPS for PA System Servers

A reliable power supply is fundamental for any critical system, especially a PA System Server in a chemical plant. Power outages cause significant downtime incidents. Surveys reveal that 33% of downtime incidents stem from power outages. This highlights the critical role of reliable power distribution units in server environments. Therefore, engineers must design robust power solutions.

Power Distribution Units (PDUs) enhance the reliability of the power supply. Intelligent monitoring and remote access allow remote control of individual outlets. This enables rebooting devices and troubleshooting without physical presence. It minimizes downtime and enhances operational efficiency. Load balancing prevents circuit overloads. It distributes power evenly across outlets, reducing the risk of unexpected shutdowns. Surge protection shields equipment from voltage spikes. This safeguards sensitive components and ensures uninterrupted operations. Environmental monitoring provides real-time data on power usage and environmental conditions. These conditions include temperature and humidity. This helps identify and prevent potential issues. Modular design enables quick replacements and scalability. It offers a plug-and-play architecture. This allows for additions or changes without disrupting operations.

PDUs also offer advanced monitoring capabilities. Remote monitoring allows data center managers to monitor real-time power use. They can also check data and event logs, and current drawn by each PDU and outlet. Remote On/Off switching provides the ability to remotely control power to individual outlets. PDUs can send alerts for abnormal conditions. These include failed power supplies, significant temperature increases, sudden power surges, or when a PDU nears its total power capacity. This prevents outages. Outlet-level monitoring enables pinpointing areas for equipment rearrangement. This frees up power capacity and identifies energy-intensive or unused equipment. PDUs containing high-efficiency transformers are 2% to 3% more efficient overall compared to those with generic lower-efficiency transformers.

Uninterruptible Power Supply (UPS) systems provide continuous power during outages. A UPS offers battery backup. It allows the PA System Server to continue operating during short power interruptions. It also provides time for a graceful shutdown during extended outages. This prevents data corruption and system damage. Engineers must size the UPS correctly. It must support the server’s power requirements for the necessary duration.

Network and Software Integration for PA System Servers

Integrating network and software components into a PA System Server requires careful planning. This ensures seamless communication and robust security within a chemical plant. Engineers must select appropriate protocols, cabling, and cybersecurity measures.

Network Protocols for PA System Server Connectivity

Effective communication relies on suitable network protocols. SIP (Session Initiation Protocol) is a widely adopted protocol for Unified Communication Systems and VoIP solutions. IP Audio Client (IPAC) devices can function as SIP clients. This allows integration into existing infrastructures using SIP as their primary communication backbone. This enables broad compatibility with various third-party vendors. For SIP, UDP (User Datagram Protocol) typically handles connection establishment and media transport on port 5060. Dante, an Audio over IP protocol, is also frequently used in the AV industry. It connects Axis network audio systems to other AV systems, often through virtual soundcards with AXIS Audio Manager Pro.

For real-time audio performance, the network must meet specific requirements. A PRAESENSA PA/VA system consumes 3 Mbit of bandwidth per active channel. It requires an additional 0.5 Mbit per channel for clocking, discovery, and control data. The maximum network latency for real-time audio performance is 5 ms. This ensures audio travels from source to destination within this timeframe. Using Gigabit switches minimizes packet delay or loss. These switches offer larger buffers and faster backplanes.

Cabling for PA System Servers in Hazardous Environments

Cabling in hazardous chemical environments demands specialized solutions. Fiber optic cables are suitable for environments with explosive fumes. They do not pose an ignition danger. This makes them a good solution for a PA System Server in these settings.

Cable glands are mechanical entry devices. They secure cables and maintain explosion protection in flammable environments. They prevent gas, vapor, or dust entry, provide strain relief, ensure earth continuity, and offer fire protection. Cable glands must match equipment certifications like ATEX, IECEx, or NEC/CEC. Barrier-type glands use compound or resin to prevent gas migration. They are ideal for Zone 1/0, Class I, Division 1 areas. Compression-type glands compress a seal around the cable sheath. They suit Zone 2/Division 2 and light industrial areas. Stainless steel is a common material choice for harsh and corrosive environments. It resists chemicals, saltwater, acids, and solvents. Protective conduits and enclosures, such as NEMA- and IP-rated options, enhance compliance and cable lifespan. Proper cable routing and management, using raised cable trays and raceways, prevent entanglement and physical damage.

Cybersecurity for PA System Server Software

Cybersecurity is crucial for PA system server software in industrial control systems. The ISA/IEC 62443 series of standards directly applies to this area. It focuses on automation and control system applications, including industrial automation and operational technology. These standards address a wide range of automation digital security challenges. Key sections cover general concepts, policies and procedures, system-level essentials, and component-specific requirements.

Integration with Plant Control Systems via PA System Servers

Integrating the PA System Server with plant control systems is crucial for modern chemical plants. This integration enables automated responses and enhances overall operational efficiency. It allows the PA system to act proactively based on real-time data from various sensors and control units. This capability significantly improves emergency response times and reduces human error.

Engineers typically use several methods for this integration.

- OPC Unified Architecture (OPC UA): This is a widely adopted standard for industrial communication. It provides a secure and reliable framework for data exchange between different systems. OPC UA allows the PA system to subscribe to data points from PLCs (Programmable Logic Controllers) or DCS (Distributed Control Systems).

- Modbus: This is another common serial communication protocol. It facilitates communication between industrial electronic devices. While older, Modbus remains prevalent in many legacy systems.

- Custom APIs (Application Programming Interfaces): Some systems require custom-developed APIs for seamless data flow. These APIs ensure specific data formats and communication protocols are met.

The benefits of this integration are substantial. It enables automatic triggering of specific announcements during emergencies. For example, a gas leak detected by a sensor can immediately activate a pre-recorded evacuation message through the PA system. This eliminates delays associated with manual intervention. Integration also allows for centralized control and monitoring of the PA system from the main control room. Operators can manage announcements, check system status, and troubleshoot issues from a single interface. This streamlines operations and improves situational awareness. Furthermore, it supports data logging and reporting, providing valuable insights for post-incident analysis and continuous improvement.

Lifecycle Management of PA System Servers

Effective lifecycle management ensures the PA System Server remains reliable and compliant throughout its operational life. This involves rigorous testing, proactive maintenance, and robust disaster recovery planning. Organizations must implement these strategies to guarantee continuous communication capabilities.

Testing Protocols for PA System Servers

Rigorous testing protocols confirm the PA System Server’s operational integrity. Functional tests verify individual components perform as expected. Integration tests ensure seamless communication between the server and other plant systems. Stress tests evaluate the system’s performance under peak load conditions. These tests confirm the server can handle high traffic volumes without degradation. Emergency scenario drills simulate real-world incidents. These drills validate the system’s ability to deliver critical messages accurately and promptly. Organizations must conduct these tests periodically. This proactive approach identifies potential issues before they escalate into critical failures.

Maintenance and Predictive Strategies for PA System Servers

Proactive maintenance extends the lifespan and enhances the reliability of PA system infrastructure. Routine maintenance tasks include applying software updates and security patches. Regular hardware inspections identify signs of wear or potential component failures. Predictive maintenance strategies utilize advanced analytics. They monitor system health in real-time. Sensors track key performance indicators for server components. This data allows teams to anticipate potential failures. They can schedule replacements or repairs before a component breaks down. This strategy minimizes unexpected downtime. It also optimizes resource allocation for maintenance activities.

Disaster Recovery for PA System Servers

A comprehensive disaster recovery plan is essential for any critical communication system. This plan outlines specific steps to restore the PA System Server after a major incident. It includes regular data backups of configurations, audio files, and system logs. Offsite storage protects these critical backups from local disasters. The plan defines Recovery Time Objectives (RTO) and Recovery Point Objectives (RPO). These metrics guide the speed and completeness of recovery efforts. Regular disaster recovery drills validate the plan’s effectiveness. These drills prepare personnel for real emergencies. They ensure rapid and efficient system restoration, minimizing communication disruptions.

Obsolescence Management for PA System Servers

Managing obsolescence for a PA System Server is crucial for long-term operational reliability in chemical plants. This process ensures the system remains functional, secure, and compliant over its entire lifecycle. Effective strategies prevent unexpected failures and costly emergency replacements. Organizations must plan for hardware and software aging.

Several strategies help manage obsolescence effectively. Retirement involves performing data wipes using certified tools or physically destroying assets. Updating asset logs with disposal details, including time, performer, and proof of data erasure, is essential. Finance departments remove assets from depreciation schedules and trigger replacement budgeting. Automating retirement workflows in IT asset management (ITAM) platforms ensures consistency. Refurbishment extends hardware life by 12-24 months. This occurs when hardware is functionally sound but underperforming due to aging components. Upgrading components, such as replacing old hard drives with SSDs or adding RAM, is common. Tagging assets as refurbished and updating records is necessary. Limiting refurbished devices to non-extensive tasks optimizes their use. Repurposing occurs when items are under-utilized or not aligned with assigned users. Reassigning devices to less-intensive operations, like training rooms or backup hardware pools, is a good practice. Resetting and reinstalling only essential software saves time. Logging saved costs demonstrates the value of refurbished equipment. Proactive management involves acting before complete failure. Predictive maintenance and refurbishments are less costly than emergency replacements. IT asset management platforms provide centralized visibility into asset age, warranty, usage, and performance data. This enables data-driven decisions.

A health group faced challenges with increasing helpdesk tickets due to hardware slowness, out-of-warranty laptops, and a lack of consistent processes for managing aging assets. By implementing strategic retirement, repurposing, and refurbishing, they aimed to optimize their IT asset lifecycle, demonstrating the practical application and benefits of these strategies.

Organizations should retire devices when they are out of warranty, underperforming, unable to run current security updates, or pose a compliance risk. Retirement is also advised if the cost to repair outweighs the device’s value. Refurbishing old laptops is worthwhile if the hardware is structurally sound. Upgrading components like RAM or SSDs can extend lifespan by 1-2 years at a fraction of the replacement cost. Utilizing an IT asset management platform effectively tracks aging hardware. This monitors age, warranty, usage, and lifecycle status from a centralized dashboard, moving away from reliance on spreadsheets.

Building a compliant PA System Server demands a holistic approach. It integrates stringent safety standards with advanced technology. Reliability and future-proofing are crucial for these systems. They ensure effective communication in chemical plants. Organizations must continuously adapt to evolving regulations and technological advancements. This proactive stance guarantees ongoing safety and operational excellence.

FAQ

What are the primary regulatory bodies for PA systems in chemical plants?

OSHA, NFPA, IEC, and ANSI establish guidelines. These bodies ensure safety and performance standards for PA systems. They cover emergency communication, fire safety, and equipment for explosive atmospheres.

Why is redundancy crucial for a PA System Server in a chemical plant?

Redundancy ensures continuous operation. It prevents communication failures during emergencies. Implementing failover mechanisms means the system remains active. This protects against single points of failure, guaranteeing critical messages always transmit.

How do hazardous zone classifications impact PA System Server design?

Classifications dictate equipment suitability. They specify the type of enclosures needed. For example, Zone 1 or Division 1 areas require explosion-proof or purged enclosures. This prevents ignition of flammable substances, ensuring safety.

What is the importance of cybersecurity for PA System Server software?

Cybersecurity protects against cyber threats. It prevents system compromise or communication disruption. Adhering to standards like ISA/IEC 62443 secures industrial control systems. This ensures the PA system functions reliably during critical events.

See Also

Top 5 Industrial Air Fryers: Essential for High-Volume Kitchens

Dishwasher Safety: Can Your Air Fryer Basket Go In?

Air Fryer Method: Perfectly Cooking Delicious Aidells Sausage Every Time

Achieve Perfect State Fair Corn Dogs Using Your Air Fryer

Air Fryer Guide: Crispy McCain Beer Battered Fries Made Easy

Post time: Jan-13-2026