Ninety percent in-house manufacturing provides unparalleled control over every production stage. This directly ensures superior quality and reliability in industrial communication systems. Complete control allows direct oversight from design to final output, guaranteeing each stage meets the highest standards. Dedicated attention to an IP PBX Telephone System, for example, ensures a higher quality final product.

Key Takeaways

- In-house manufacturing gives full control over making industrial communication systems. This helps make sure they are very good quality and work well.

- Making things in-house means you can find problems fast and fix them. This helps make products better and keeps them working smoothly.

- Having most manufacturing in-house makes the supply chain strong. It means fewer problems getting parts, even when things go wrong in the world.

Unparalleled Control and Quality Assurance for Industrial Communication Systems

Integrated Design and Development

Integrated design and development form the bedrock of high-quality industrial communication systems. This approach ensures every aspect of a product, from concept to final production, aligns with stringent quality standards. By integrating design and development, manufacturers gain comprehensive control over the entire process.

Integrated Process Systems (IPS) lead to improved quality control. Automated systems ensure each product meets standards, reducing the likelihood of defects. Data collected at various stages can be analyzed immediately to highlight trends or any deviations for corrective actions and measurements. This strict quality assurance guarantees final products comply with stringent industry regulations and meet customer expectations.

Industry best practices guide this integrated approach. Manufacturers integrate legacy infrastructure using gateways or hybrid architectures. They design robust shielding, select appropriate frequencies, and conduct site surveys to mitigate electromagnetic interference (EMI) and industrial noise. Planning for scalability and bandwidth accommodates future growth in devices and data. Implementing security measures like network segmentation, encryption, and regular audits is crucial. Choosing communication technologies such as Time-Sensitive Networking (TSN) or private 5G ensures predictable timing for control loops and addresses latency. Deploying network monitoring, fault detection, and diagnostic tools facilitates effective maintenance and monitoring. Prioritizing standards and protocols like EtherNet/IP, PROFINET, and OPC UA ensures vendor interoperability and flexibility. Addressing interference and signal degradation occurs through careful site surveys, directional antennas, and hybrid wired fallback paths. Overcoming latency and jitter issues uses deterministic networking protocols, edge computing, and Quality of Service (QoS) prioritization. Enhancing security and segmentation employs network segmentation, zero-trust architecture, encryption, and continuous monitoring. Integrating with legacy systems uses protocol gateways, retrofit sensors, or adapters. Managing cost and ROI uncertainty begins with phased pilots, measuring ROI, and scaling gradually. Facilitating change management and training involves hands-on training, documentation, and establishing governance policies for new systems.

Meticulous Component Sourcing and Verification

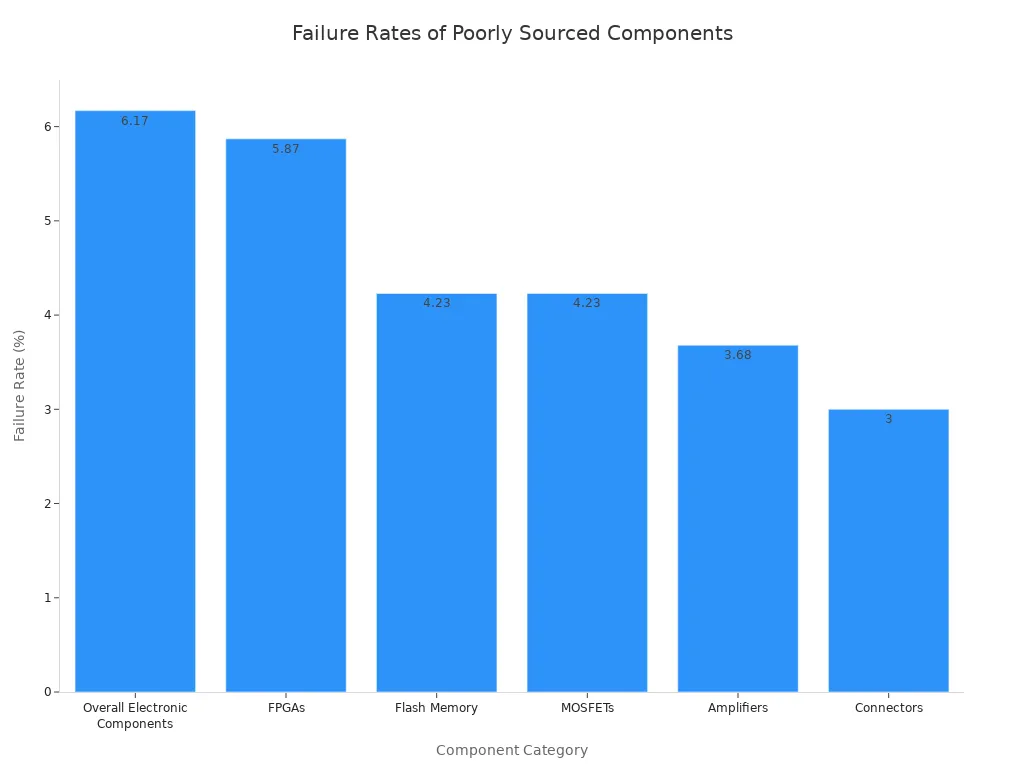

Meticulous component sourcing and verification are critical steps in maintaining product integrity. Poorly sourced components introduce significant risks, potentially compromising the entire system’s reliability. The failure rates associated with unverified parts highlight the importance of rigorous checks.

A 6.17% failure rate, though seemingly low, can translate to hundreds of defective parts in high-volume orders. This poses a real risk in critical sectors like aircraft navigation or medical diagnostics. The report reflects a market where counterfeit infiltration remains a threat. Failure to verify components could lead to costly recalls or safety incidents. Poor communication regarding specifications leads to rework, returns, and warranty claims. It also results in lost sales and damaged customer relationships. Businesses compensate for poor communication with excessive quality control measures, including third-party inspections, redundant testing, and expanded QC teams. Poor communication fosters mistrust, leading to relationship breakdown and the expensive process of finding and onboarding new suppliers.

Effective verification methods ensure component quality. Manufacturers query plant host database systems for component build requirements. They broadcast build information to operator assembly stations. They provide immediate quality feedback to assembly operators before the part leaves the station. They collect assembly data from assembly stations. In-process testing occurs throughout the assembly process. End-of-line testing and verification of the completed part are also performed. All assembly information is recorded in a database archive. Other effective methods include quality inspections, failure testing (stress testing), Six Sigma, Root Cause Analysis (RCA), Statistical Process Control (SPC), Lean manufacturing, and Total Quality Management (TQM). These comprehensive strategies ensure every component meets the highest standards before integration into Industrial Communication Systems.

Precision Assembly and In-Process Testing

Precision assembly and in-process testing are vital for the long-term reliability of industrial communication systems. Each component must fit together perfectly to ensure optimal performance and durability. This meticulous execution prevents malfunctions and reduces the need for costly rework or recalls.

Precision in cable and wire harness assembly services is fundamental to modern electronic connectivity. These services combine engineering precision, quality materials, and manufacturing expertise to create reliable interconnections. This structured approach ensures each harness meets required specifications and withstands environmental stresses. It reduces errors and significantly enhances the long-term reliability of the product. This is crucial for applications where consistent and durable performance is non-negotiable.

Precision assembly significantly enhances the long-term reliability of systems. It ensures all components fit together precisely. This meticulous execution prevents malfunctions, reduces the need for costly rework or recalls, and allows the final product to operate seamlessly and perform at optimal levels. The accuracy in assembly also leads to improved functionality and longevity. These are critical for consistent and error-free operation.

In the electronics manufacturing industry, high-precision assembly drives reliable performance and meets customer expectations. Investing in precision assembly technologies allows manufacturers to achieve improved product quality, reduced rework, and higher yields. Conversely, errors in the assembly process can lead to costly recalls and reputational damage. This commitment to precision ensures complex electronic devices maintain long-term reliability and functionality.

In-process testing complements precision assembly by identifying and addressing issues at every stage of production. This continuous monitoring ensures any deviation from quality standards is immediately detected and corrected. This proactive approach prevents defects from propagating through the manufacturing process, ultimately delivering a superior and reliable final product.

Enhanced Traceability and Continuous Improvement in Industrial Communication Systems

Ninety percent in-house manufacturing significantly boosts traceability and continuous improvement. This level of control allows companies to track every product detail. It also enables them to refine processes constantly. This leads to higher quality and more reliable systems.

Rigorous Multi-Stage Testing and Feedback Loops

Rigorous multi-stage testing and feedback loops are essential for product excellence. Manufacturers conduct tests at every production phase. This includes individual components, sub-assemblies, and final products. Each test identifies potential issues early.

For example, Joiwo performs comprehensive testing:

- Component-level testing: This verifies individual parts meet specifications before assembly.

- In-process testing: Technicians check functionality during assembly. This catches errors immediately.

- System integration testing: Engineers ensure all parts work together as a complete system.

- Environmental testing: Products undergo stress tests for temperature, humidity, and vibration. This confirms durability in harsh industrial settings.

Feedback from these tests goes directly to design and production teams. This creates a continuous improvement cycle. Teams analyze test results. They then implement necessary adjustments. This iterative process refines product designs and manufacturing methods. It ensures each new batch benefits from previous learnings. This proactive approach prevents defects and enhances overall product quality.

Full Product Traceability and Accountability

Full product traceability and accountability are direct benefits of extensive in-house manufacturing. Companies can track every component from its origin. They also monitor each step of the manufacturing process. This includes who worked on what and when.

This detailed record-keeping means manufacturers can quickly pinpoint the source of any issue. If a problem arises, they know exactly which batch of materials or which production stage caused it. This speeds up problem resolution. It also ensures accountability within the production team. This level of transparency builds trust with customers. They know the company stands behind its products. It also allows for precise recall management if ever needed.

This comprehensive traceability extends to the entire lifecycle of Industrial Communication Systems. From raw material to finished product, every detail is logged. This ensures consistent quality and performance. It also supports regulatory compliance.

Faster Innovation and Customization Capabilities

In-house manufacturing provides faster innovation and customization capabilities. Direct control over production allows for rapid prototyping. Engineers can quickly test new designs. They can also implement improvements without external delays. This agility means companies can respond faster to market demands. They can also integrate new technologies more quickly.

This capability also extends to customization. Clients often have unique requirements for their industrial environments. With in-house manufacturing, companies can tailor products efficiently. They can modify designs or integrate specific features. This personalized approach ensures the communication system perfectly fits the client’s needs. This flexibility fosters stronger client relationships. It also positions the company as a leader in specialized solutions. This streamlined process from concept to delivery accelerates product development cycles. It also enhances customer satisfaction.

Risk Mitigation and Supply Chain Resilience for Industrial Communication Systems

Ninety percent in-house manufacturing significantly strengthens supply chain resilience. It reduces reliance on external vendors. This approach minimizes risks associated with global supply chain disruptions.

Reduced External Dependencies and Consistent Supply

In-house manufacturing provides a consistent supply of critical components. A vertically integrated partner offers enhanced supply consistency compared to traditional manufacturing partners. This is because a single vendor manages multiple concurrent processes.

| Feature | Vertically Integrated Partner | Traditional Manufacturing Partners |

|---|---|---|

| Supply Consistency | Enhanced through single vendor solution, multiple concurrent processes, and reduced lead times | Limited by single-process specialization and longer lead times |

| Lead Times | Weeks faster than traditional component procurement | 2-3 Months |

| Quality Control | Integrated across all manufacturing processes, streamlined communication, single source accountability, unified quality standards, cross-process inspection | Fragmented, leading to potential inconsistencies |

A vertically integrated partner performs critical steps like machining, coating, and assembly without shipping components between different facilities. This integration leads to faster production and more consistent quality. It also simplifies project management. When one partner manages multiple processes, they understand how each process impacts others. This allows for optimization across the entire manufacturing sequence. This is crucial for a consistent supply of components for Industrial Communication Systems. In high-stakes industries, time-critical innovation demands accelerated production without compromising quality. Integrated manufacturing approaches are vital for ensuring a swift and consistent supply of components. This meets urgent timelines and maintains technological advantages.

Proactive Problem Resolution and Operational Efficiency

In-house manufacturing enables proactive problem resolution. Teams can quickly identify and address issues. This direct control over production processes allows for immediate corrective actions. It prevents minor problems from escalating. This approach significantly improves operational efficiency. It minimizes downtime and reduces production delays. Companies maintain tight control over quality standards. They ensure every product meets rigorous specifications. This leads to more reliable products and greater customer satisfaction.

Ninety percent in-house manufacturing guarantees superior quality and reliability. It achieves this through complete control, robust quality assurance, agile innovation, and resilient supply chains.

This integrated approach ensures consistent performance for Industrial Communication Systems. It also fosters long-term strategic partnerships, providing clients with dependable solutions.

FAQ

How does 90% in-house manufacturing improve product quality?

Ninety percent in-house manufacturing provides complete control over every production stage. This ensures superior quality and reliability for industrial communication systems.

What are the benefits of full product traceability?

Full traceability allows quick identification of issue sources. It speeds up problem resolution and ensures accountability within the production team.

How does in-house manufacturing enhance supply chain resilience?

In-house manufacturing reduces external dependencies. It minimizes risks from global supply chain disruptions and ensures a consistent component supply.

Post time: Jan-08-2026