Prioritize safety and operational continuity in hazardous oil and gas environments. You need to understand the essential considerations for selecting an ATEX Certified explosion-proof telephone. The market for Explosion Proof Telephones is growing, projected to reach USD 3.5 billion by 2033. Make an informed decision by evaluating 10 critical factors for your Explosion Proof Telephones (ATEX) needs.

Key Takeaways

- Choose an ATEX certified phone. It must match your hazardous work zone. This keeps your team safe.

- Look for phones with high IP ratings. They resist dust and water. This makes them last longer in tough places.

- Pick a phone with good battery life and clear sound. It should also be easy to use with gloves. This helps your team communicate well and stay safe.

Understanding Hazardous Zones and ATEX Certified Requirements

What are ATEX and FCC Certifications?

ATEX certification confirms equipment or products are safe for use in explosive atmospheres. ATEX stands for “Atmosphères Explosibles.” It refers to two EU directives. These directives set safety requirements for hazardous areas. Certification ensures equipment meets stringent safety and quality requirements. ATEX covers both equipment and workplaces. For equipment, ATEX certification is crucial for manufacturing and selling items used in hazardous areas. It ensures they prevent ignition sources. For workplaces, ATEX mandates employers to classify areas with explosive atmospheres into zones. They must develop an Explosion Protection Document (EPD) to ensure safety and prevent explosions.

FCC certification means a product complies with the standards required for marketing. It signifies that the Federal Communications Commission (FCC) or a Telecommunication Certification Body (TCB) has approved the equipment. This approval confirms an electronic device is safe to use. It does not emit excessive RF radiation or cause electromagnetic interference (EMI). By law, electronic devices sold in the United States must comply with FCC regulations. The FCC mark on a product indicates its compliance. The primary purpose of FCC certification is to ensure radio frequency emissions are within approved limits. This prevents harmful interference with other electronic equipment or wireless communication services. Devices fall into Class A (commercial) or Class B (residential) categories. Class B devices have more stringent requirements. Any electronic device that uses RF technology or emits RF energy generally needs FCC certification.

Why Certifications are Crucial for Oil and Gas

In oil and gas environments, safety is paramount. You operate in areas where explosive atmospheres are common. You need equipment that will not cause sparks or ignition. An ATEX Certified phone prevents catastrophic accidents. FCC certification ensures your communication devices do not interfere with critical systems. These certifications protect your personnel. They also protect valuable assets. They ensure operational continuity in hazardous settings.

Hazardous Zone Classifications Overview

Hazardous areas have specific classifications. These classifications help you choose the right ATEX Certified equipment.

- Zone 0: An area where an explosive atmosphere is continuously present. It occurs for extended periods or frequently.

- Zone 1: An area where an explosive atmosphere is likely to occur occasionally. This happens during normal operations. It could be due to repair, maintenance, or leakage.

- Zone 2: An area where an explosive atmosphere is not likely to occur during normal operations. If it does, it will only persist for a short duration. Accidents or unusual operating conditions cause these hazards.

Factor 1: Certification Levels for ATEX Certified Phones

Matching Phone Rating to Hazardous Area

You must select an ATEX Certified phone that matches your specific hazardous area. The ATEX directive categorizes products based on risk. Category 1 products suit higher-risk situations. They offer exceptional safeguarding. These products guarantee protection even with two simultaneous faults. This emphasizes reliability. Category 2 products provide robust protection. They can withstand a single fault. This ensures reliable safety, but with lower fault tolerance than Category 1. These categories apply to various safety equipment, including mobile devices.

Consider the frequency of an explosive atmosphere in your area.

| Zone | Frequency Of Explosive Atmosphere | Safety Measures Required |

|---|---|---|

| Zone 0 | Continuously or for long periods | Use of Intrinsically Safe products, strict safety measures |

| Zone 1 | Likely under normal operating conditions | Meticulous selection and installation of compliant electrical equipment |

| Zone 2 | Likely only under abnormal conditions or for short durations | Adoption of Zone 1-compliant electrical equipment, heightened safety precautions |

ATEX Zones and FCC Classes Explained

Understanding ATEX zones helps you choose the correct equipment.

- Zone 0: An explosive atmosphere is present continuously or for extended durations. This high-risk zone demands Intrinsically Safe products. These products prevent ignition from electrical energy.

- Zone 1: An explosive atmosphere is likely under normal operating conditions. This zone requires careful selection and installation of electrical equipment. It must comply with ATEX categories, temperature, gas groups, and ignition temperature requirements.

- Zone 2: An explosive atmosphere is only likely under abnormal conditions or for short durations. This zone has lower risk than Zone 0 or 1. Safety precautions remain paramount. Electrical equipment suitable for Zone 1 can provide added protection here.

FCC classes also guide your selection. Class A devices are for commercial use. Class B devices are for residential use. Class B has stricter emission limits. You ensure your communication devices do not interfere with other electronics by choosing FCC-compliant phones.

Factor 2: Ingress Protection (IP) Rating

Resistance to Dust and Water

You must consider the Ingress Protection (IP) rating when you select an explosion-proof phone. This rating tells you how well a device resists dust and water. The IP code has two digits. The first digit shows protection against solid objects like dust. The second digit shows protection against liquids like water.

Here is what each digit means:

| Digit Level | Protection Against Solids (First Digit) | Protection Against Liquids (Second Digit) |

|---|---|---|

| 0 | No protection | No protection |

| 1 | Objects >50 mm (e.g., back of hand) | Dripping water (vertical) |

| 2 | Objects >12.5 mm (e.g., fingers) | Dripping water (when tilted 15°) |

| 3 | Objects >2.5 mm (e.g., tools, thick wires) | Spraying water (up to 60° from vertical) |

| 4 | Objects >1 mm (e.g., wires, slender screws) | Splashing water from any direction |

| 5 | Dust protected (limited ingress allowed) | Low-pressure water jets from any direction |

| 6 | Dust-tight (no ingress of dust) | Powerful water jets from any direction |

| 7 | N/A | Immersion in still water (15 cm to 1 m for 30 min) |

| 8 | N/A | Continuous immersion in water (depth specified by manufacturer) |

| 9K | N/A | High-pressure, high-temperature steam jets |

Note: ‘N/A’ for solid protection indicates that these levels are typically associated with a ’6′ for dust-tightness when paired with higher liquid protection ratings like IP67, IP68, and IP69K.

Common IP ratings you will see include:

- IP67: This rating means complete protection against dust. It can also withstand temporary submersion in still water. This is usually between 15 cm and 1 meter deep for at least 30 minutes.

- IP68: This offers full dust protection. It provides a higher level of water protection. It allows for continuous submersion in water deeper than 1 meter. The manufacturer specifies the exact depth and duration.

- IP65: An IP65 rating means the device is fully dust-tight. It is protected against low-pressure water jets from any direction. It handles rain and wash-downs but not submersion.

- IP69K: This is the highest IP rating. It shows complete dust protection. It resists high-pressure, high-temperature steam jets.

Importance in Harsh Environments

You work in environments with constant exposure to dust, moisture, and sometimes even chemicals. A high IP rating protects your phone from these elements. It prevents internal damage. This ensures your communication device remains functional and reliable. A phone with a robust IP rating will last longer. It reduces the need for frequent replacements. This saves you money and prevents operational downtime. You need a phone that can withstand the daily challenges of your hazardous workplace.

Factor 3: Material Durability and Construction

Withstanding Extreme Temperatures

You operate in environments with extreme temperatures. Your explosion-proof phone must endure these conditions. It needs to function reliably in both intense heat and severe cold.

- IECEx or ATEX-certified explosion-proof devices work in temperatures from -10°C to +55°C. This ensures durability in various settings.

- Heavy-duty telephones for oil and gas projects operate within an even wider range, from -40°C to +70°C.

This robust temperature tolerance guarantees your communication remains uninterrupted, no matter the weather.

Corrosion and Impact Resistance

Hazardous environments often expose equipment to corrosive substances and physical impacts. You need a phone built from materials that resist these challenges. Strong construction prevents damage and extends the phone’s lifespan.

Manufacturers use specific materials to ensure your phone withstands harsh conditions:

| Material | Corrosion Resistance | Impact Resistance | Other Relevant Properties |

|---|---|---|---|

| Aluminum | Excellent | Good | Lightweight, thermal conductivity, dissipates heat |

| Stainless Steel | Exceptional | Excellent | Strength, endures harsh conditions, resists chemicals and saltwater |

| Cast Iron | Good | Robust | Heavy-duty, absorbs and dissipates energy |

| Fiberglass Reinforced Polyester (FRP) | Excellent | Good | Electrical insulation, reduced weight, no rust/degradation |

| Polycarbonate | Excellent | Good | Electrical insulation, reduced weight, no rust/degradation |

These materials ensure your phone resists rust, chemicals, and physical shocks. This protects your investment and maintains operational safety.

Factor 4: Communication Technology Options

Wired vs. Wireless Capabilities

You must choose between wired and wireless communication for your explosion-proof phone. Each option offers distinct advantages. Wired phones provide stable and secure connections. They are reliable in fixed locations. Wireless phones offer flexibility and mobility. You can move freely within your hazardous area. Your choice depends on your operational needs. Consider the layout of your facility. Think about how your team works.

VoIP, Analog, Wi-Fi, GSM, Satellite Options

You have several technology options for communication.

- VoIP (Voice over Internet Protocol): VoIP phones use your existing network infrastructure. They offer advanced features. The GAI-Tronics Hazardous Area PA 352 VoIP phone has a durable aluminum body. It is weatherproof. It includes tone dialing and volume control. The Joiwo JR101-FK-VoIP phone is another option. It features a rugged aluminum enclosure with an IP67 rating. It has a noise-cancelling microphone. This phone works in temperatures from -40°C to +70°C. It supports SIP 2.0 protocol. You can use VoIP phones in:

- Tunnels

- Mining operations

- Chemical plants

- Power plants

- Other heavy-duty industrial applications

- GSM (Global System for Mobile Communications): GSM phones offer mobile communication. They are useful for personnel on the move.

Feature Specification 2G GSM Bands 850 / 900 / 1800 / 1900 MHz Connectivity 4G / LTE (SIM unlocked), WiFi 2.4 Ghz and 5 Ghz, Bluetooth® 4.2, GPS, NFC These phones often have robust features. They include MMS, Bluetooth® 3.0, and integrated office functions. Some models offer lone worker protection. They have scratch and impact-resistant Gorilla® Glass displays. You find GSM phones in:

- Global oil and gas industry

- Petrochemical plants

- Mining and underground processes

- Hazardous areas (Zone 1, Zone 2, Zone 22, Division 2)

- Analog: Analog phones are simple and reliable. They use traditional telephone lines.

- Wi-Fi: Wi-Fi phones connect to your wireless network. They offer mobility within Wi-Fi coverage.

- Satellite: Satellite phones provide communication in remote areas. They work where other networks are unavailable.

You select the technology that best fits your communication requirements.

Factor 5: Audio Clarity and Noise Cancellation

Ensuring Clear Communication

You need clear communication in hazardous environments. This is vital for safety and efficiency. Your explosion-proof phone must deliver crisp audio. This reduces misunderstandings and errors. Industry standards emphasize clear communication. For example, Delivered Audio Quality (DAQ) standards, like those in NFPA 1225, focus on real-world clarity. DAQ 3.0 means you hear clear and easily understood communication with minor effort. Many cities now adopt DAQ 3.4. This represents superior clarity. You need no effort to understand speech. Technologies like Active Noise Cancellation (ANC) detect and cancel ambient noise. This allows only the voice to pass through. High-definition audio also transmits voice signals clearly. This reduces the risk of errors.

Performance in Noisy Industrial Settings

Industrial settings are often very noisy. Your phone must perform well in these conditions. High decibel levels can make communication difficult. Effective noise cancellation is crucial. Active Noise Cancellation (ANC) is highly effective. It reduces background noise. This improves your focus. It also protects your hearing. ANC works well against sounds over 85 decibels. It is especially good for constant, low-frequency noises. Adaptive ANC is more advanced. It automatically adjusts to tune out unwanted noise. Hybrid ANC combines different ANC methods for better noise reduction. Passive Noise Cancellation (PNC) is also available. It works best for mid- to high-frequency noises. However, PNC is less effective in high-decibel environments. It offers limited decibel reduction. You need a phone with robust noise cancellation. This ensures your messages are always heard.

Factor 6: Power Supply and Battery Life

You need a reliable power source for your explosion-proof phone. This ensures continuous communication in hazardous areas. Battery life is a critical consideration. It directly impacts your operational efficiency and safety.

Reliability in Remote Areas

You often work in remote locations. Charging stations are not always available. A long battery life is essential for your ATEX mobile phone. You need devices that support all-day operation. Some models offer hot-swappable battery options. This allows you to continue using your device without delays. You can quickly exchange a depleted battery for a charged one. This ensures uninterrupted communication during long shifts.

Longevity in Power-Limited Zones

Long-lasting battery life is crucial for explosion-proof mobile phones. This is especially true in industrial settings. Workers on extended shifts or in remote areas have limited charging access. Some models operate for several days on a single charge. This depends on your usage patterns. You can compare battery life across different models to find the best fit for your needs.

| Model | Battery Life |

|---|---|

| Bartec Pixavi Phone | Up to 10 hours |

| Ecom Smart-Ex 02 DZ1 | Up to 12 hours |

| i.safe MOBILE IS530.1 | Up to 16 hours |

| Dorland TEV8 | Up to 20 hours |

| Sonim XP8 | Up to 35 hours |

You can see the range of battery life available:

This extended battery performance ensures your team stays connected. It reduces downtime for charging.

Factor 7: Ease of Installation and Maintenance

Practical Deployment Considerations

You need an explosion-proof phone that is easy to install. Simple installation saves you time and reduces labor costs. Look for phones with clear instructions and straightforward mounting options. You want a device that connects easily to your existing communication systems. Consider if you need specialized tools or complex wiring. A phone designed for quick setup helps you get your operations running faster. This minimizes disruption in your hazardous environment.

Upkeep in Industrial Settings

Regular maintenance keeps your explosion-proof phone working correctly. Proper upkeep ensures safety and extends the device’s lifespan. You must follow a consistent maintenance schedule. This prevents unexpected failures.

Here is a recommended maintenance schedule for these devices:

| Maintenance Task | Suggested Frequency |

|---|---|

| Visual Inspection | Monthly |

| Functional Testing | Quarterly |

| Electrical Safety Checks | Annually |

| Battery Review/Replacement | Every 18–24 months |

| Firmware/Software Updates | As released (quarterly ideal) |

| Calibration (if applicable) | Every 6–12 months |

| Record Audit and Validation | Annually |

You should ensure trained personnel perform all maintenance tasks. These individuals must have certification in hazardous area electrical safety. Authorized technicians, approved by your safety officer or the original equipment manufacturer (OEM), should handle these checks. They need proper equipment, including ESD-safe tools and explosion-proof lighting.

You can optimize your maintenance efforts with these best practices:

- Implement a digital CMMS for automated schedules and alerts.

- Tag devices with RFID or barcodes to track service history.

- Train field teams annually on safety and device handling.

- Centralize spare parts and use only certified replacements from OEMs.

- Conduct mock audits to ensure documentation is ready for inspection.

Factor 8: User Interface and Ergonomics

Usability with Gloves

You often wear heavy gloves in hazardous environments. Your explosion-proof phone must be easy to use with them. Many intrinsically safe phones are engineered for use by workers wearing heavy gloves. They feature large buttons. This makes pressing them simple and accurate. Some phones also offer voice commands. This allows you to operate the device without removing your gloves. These design choices enhance usability. They ensure you can communicate effectively and safely.

Visibility in Low Light and Emergency Features

You work in areas with poor lighting. Your phone’s display must be clear and visible. This ensures you can read information quickly. Emergency features are also critical for your safety.

- Man Down Alarm: This feature uses sensors. It detects unusual orientations or a lack of movement. If you do not respond to prompts, it automatically triggers an alarm. This signals for help. It is very useful when you work alone. This alarm ensures a quick response to emergencies. It can save lives. It also increases your confidence. You know assistance is available.

- SOS Feature: This is a manual distress signal. You activate it yourself. It sends messages or calls to pre-set emergency contacts. It includes your GPS location. This allows for rapid deployment of emergency services. This feature adds an extra layer of security. It provides precise location tracking for quick rescue operations.

These features ensure your safety and clear communication in challenging conditions.

Factor 9: Integration with Existing Systems

Compatibility with Current Infrastructure

You need an explosion-proof phone that works with your current systems. This ensures smooth operations. Many industrial phones use open-standard communication protocols. For example, Joiwo’s heavy-duty VoIP systems often build on Open Standard SIP technology. They also use Open Standard Modbus TCP/UDP technology. These protocols allow easy connection. You can integrate these phones with your existing IT infrastructure. They also connect to SCADA systems. Any IP-based PBX and network system will work. This means your new phone will fit right into your current setup. It avoids costly overhauls.

Seamless Communication Network

Creating a seamless communication network is vital. Your explosion-proof phone needs to connect well with everything. Look for phones with strong connectivity features. These include WLAN 6 for local access. You also need 4G/LTE and 5G for remote operations. Bluetooth and NFC help with peripheral pairing. GPS/GNSS provides location tracking. These features ensure real-time data exchange.

Your phone must also work with your operational technology (OT) and information technology (IT) systems. This includes SCADA for process monitoring. It also covers CMMS for maintenance updates. IIoT systems gather sensor data. All accessories must also meet safety certifications. This prevents ignition hazards. It keeps your system compliant. Consider deployment methods like zero-touch registration. Use Mobile Device Management (MDM) for central control. Implement strong security measures. These include VPNs and encryption. This creates a secure and efficient communication network.

Factor 10: Manufacturer Reputation and Support

You must choose a manufacturer with a strong reputation. This ensures the reliability and longevity of your explosion-proof phone. A reputable supplier offers peace of mind. They provide quality products and excellent support.

Supplier Reliability and Certifications

You need to evaluate a supplier’s reliability. Look for manufacturers who comply with international safety standards. They must hold valid certifications like ATEX (EU), IECEx (international), UL/CSA (North America), and CCC (China). You should ask for traceable evidence of compliance. This includes test reports and certification documents. Reputable suppliers also have robust quality control and testing capabilities. They often have in-house testing facilities. These facilities simulate thermal, electrical, and mechanical stress. Their QC process flow should be transparent. It covers component inspection to final product validation. Third-party audit reports also provide assurance.

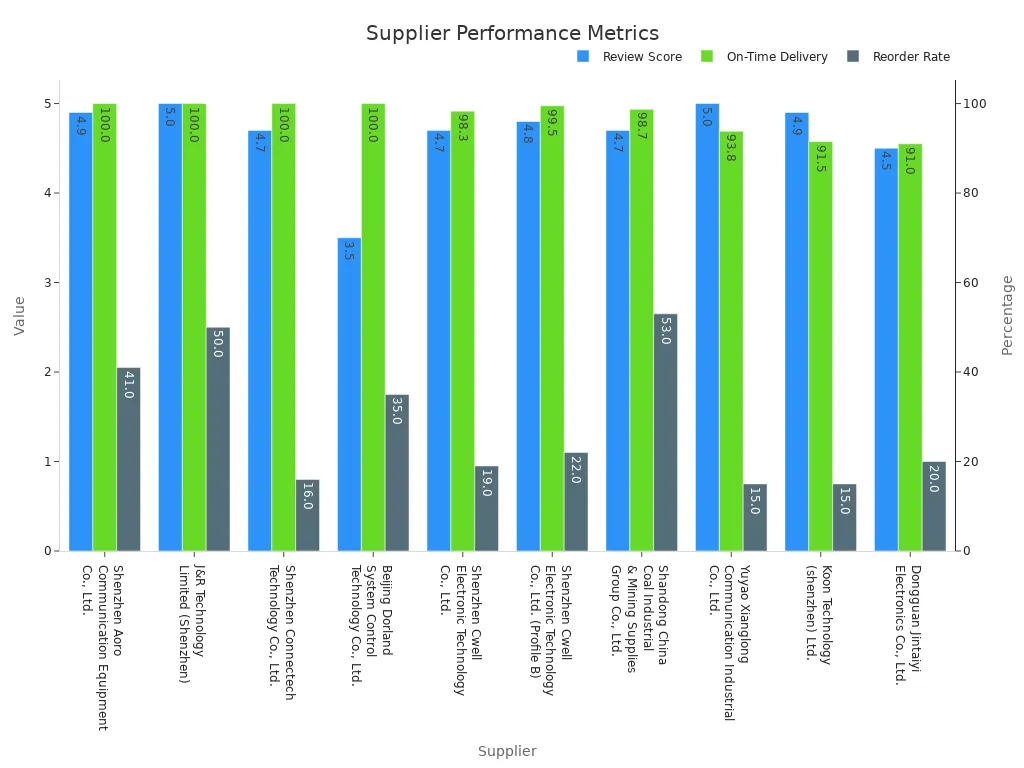

You can assess operational reliability through key performance indicators:

| Supplier | Review Score | Avg. Response Time | On-Time Delivery | Reorder Rate |

|---|---|---|---|---|

| Shenzhen Aoro Communication Equipment Co., Ltd. | 4.9 / 5.0 | ≤1h | 100.0% | 41% |

| J&R Technology Limited (Shenzhen) | 5.0 / 5.0 | ≤2h | 100.0% | 50% |

| Shenzhen Connectech Technology Co., Ltd. | 4.7 / 5.0 | ≤3h | 100.0% | 16% |

| Beijing Dorland System Control Technology Co., Ltd. | 3.5 / 5.0 | ≤4h | 100.0% | 35% |

| Shenzhen Cwell Electronic Technology Co., Ltd. | 4.7 / 5.0 | ≤2h | 98.3% | 19% |

| Shenzhen Cwell Electronic Technology Co., Ltd. (Profile B) | 4.8 / 5.0 | ≤3h | 99.5% | 22% |

| Shandong China Coal Industrial & Mining Supplies Group Co., Ltd. | 4.7 / 5.0 | ≤4h | 98.7% | 53% |

| Yuyao Xianglong Communication Industrial Co., Ltd. | 5.0 / 5.0 | ≤3h | 93.8% | <15% |

| Koon Technology (shenzhen) Ltd. | 4.9 / 5.0 | ≤2h | 91.5% | <15% |

| Dongguan Jintaiyi Electronics Co., Ltd. | 4.5 / 5.0 | ≤2h | 91.0% | 20% |

This chart illustrates how different suppliers perform across various metrics, including review score, on-time delivery, and reorder rate.

You should also verify certifications. Analyze vendor track records. Benchmark competitor offerings. Forecast growth and demand. Assess scalability. Ensure regulatory compliance. Check innovation capabilities.

Post-Purchase Service and Warranty

You need excellent post-purchase service. A strong warranty protects your investment. Evaluate the manufacturer’s after-sales support. Consider their customer service responsiveness. This ensures you receive help when you need it. A reliable vendor offers comprehensive technical support. They provide spare parts availability. This minimizes downtime. You should also consider the total cost of ownership. This includes maintenance, durability, and upgradeability. It is not just the initial purchase price. This long-term view helps you make a cost-effective decision.

Making the Right Choice: A Decision Framework

Prioritizing Factors for Operational Needs

You must prioritize factors for your operational needs. Start with a Risk Assessment Process: Zone Classification Guide. Understand OSHA regulations. These classify hazardous locations. For example, Zone 0 needs intrinsically safe equipment. This is due to continuous explosive atmospheres. Zone 1 and 2 may use intrinsically safe or explosion-proof options. Next, consider Power Requirements Analysis. Intrinsically safe equipment uses limited electrical energy. Explosion-proof enclosures handle high-power applications. Evaluate Cost-Benefit Considerations Across Equipment Lifecycle. This includes upfront costs and regulatory compliance. Also, think about installation complexity. Finally, assess Maintenance Accessibility. Intrinsically safe equipment allows maintenance while powered. Explosion-proof equipment needs a complete power shutdown.

Checklist for Evaluating Potential Phones

You need a clear checklist to evaluate potential phones. First, verify Certifications. Ensure valid ATEX, IECEx, or UL/CSA certifications. These must match your specific hazard class. Look for an Ingress Protection (IP) Rating of at least IP68. This ensures dust and water resistance. Check for Durable Casing. It should be shockproof and drop-proof. A Long Battery Life is crucial for extended shifts. Aim for at least 12 hours. Consider Glove-Compatible Touchscreen and Noise-Cancelling Microphones. These ensure clear communication in loud areas. Also, check for Push-to-Talk (PTT) for instant team communication. An Advanced Camera helps with inspections. Verify Battery Safety. Batteries must be non-sparking and thermally stable. Avoid uncertified clones. Do not use third-party modifications.

You can now confidently select ATEX and FCC certified explosion-proof telephones. This ensures safety, enhances communication, and maintains operational efficiency. You will navigate challenging hazardous environments with reliable communication solutions. Make an informed decision for your team’s protection.

FAQ

What is the main difference between ATEX and FCC certifications?

ATEX ensures equipment is safe in explosive atmospheres. FCC certifies devices do not cause harmful electromagnetic interference. You need both for hazardous environments.

Why is a high IP rating crucial for explosion-proof phones?

A high IP rating protects your phone from dust and water. This prevents internal damage. It ensures reliable operation in harsh industrial settings.

What does “intrinsically safe” mean for an ATEX phone?

Intrinsically safe means the phone prevents ignition. It limits electrical and thermal energy. This makes it safe for use in highly explosive atmospheres like Zone 0.

Post time: Jan-08-2026